I am trying to make a remote control car using an Arduino Uno and IR receiver modal VS1838B. The system worked as planned except that IR receiver gets erratic after any one motor spins.

- upon starting up, all functionalities works as planned

- after 1 motor spins , the IR receiver will barely receive.The light on the receiver will stop blinking until the motor stops.

- If I disconnect the motors, the IR receiver will receive normally.

I suspect that there is a current affecting it after the motor starts spinning

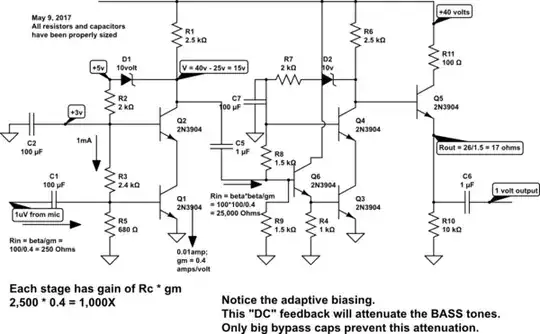

I've included my circuit diagram below.

- Pin 11 connects to IR receiver

- Pin 5 activates the transistor for the left wheel

- Pin 6 activates the transistor for the right wheel

- The power source for the IR receiver is different from the motor

- All the ground actually connects back to the UNO ground. Simplified it below.

EDIT:

- So I did an experiment to isolate and check if it was the motor/EMI that might be causing the IR receiver not to receive properly. I changed one motor with a light bulb and tested if activating the light bulb will affect the receiver. The result was that activating the light bulb did not affect it while activating the remaining motor affected it. Hence I am quite sure that the motor/EMI is causing the receiver to be erratic.

- I am not sure how to place the ceramic capacitor, so I drew a diagram of what I think it could be. Is this correct?