You don't need to have a triangle-wave or a PWM for that matter to generate a sine wave. You could use hysteresis modulation which does not require a PWM. However, the switching frequency is variable with a hysteresis modulation and it might require more computing power.

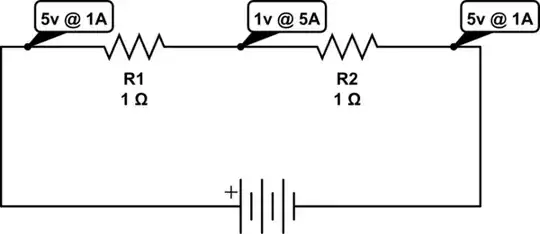

If you need a PWM, a triangle wave is the way to go, a sawtooth wave would cause problems for H-Bridges and 3-phase inverters/rectifiers. The top transistors or the bottom transistors would all stop conducting at the same time. While with a triangle wave, the top and bottom transistor of different branches will not start conducting at the same time except if the duty cycle is the same for all branches.

Edit : In the case of 3-phase rectifier/inverter using, here's the comparison between sawtooth PWM and triangle PWM. As you can see, with the sawtooth, your transition from the zero-vector "000" to the zero-vector "111" , something you don't see with the triangle wave. With the triangle wave, transistors do not switch at the same time

Another reason why a triangle wave is better. It is easier to sample signals. With the triangle wave, you can set the ADC trigger when the triangle wave is at 0 or 100%, because at these points you are assured that no transistors will switch. I added arrows on the graph to highlight the sampling instants. With the sawtooth wave, no matter where you sample, there could be a transistor switching.

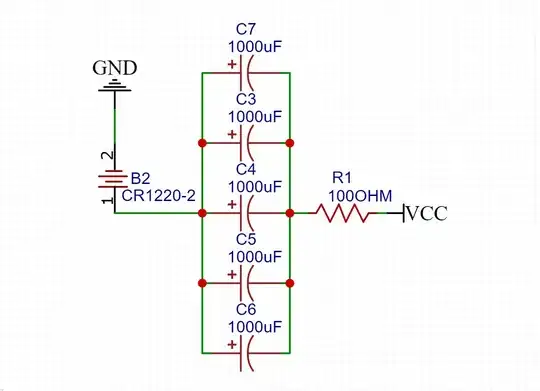

Edit 2 : The last image represents the PWM for a space-vector modulation from 0 to 60 degrees with 1 zero-sequence vector "000". You can see easily that only one transistor switch at a time. The PWM frequency used is 2400 Hz. In real-life, 2400 Hz is a bit low, it's more usual to see 10 kHz and more for PWMs. You can also see Va, Vb and Vc