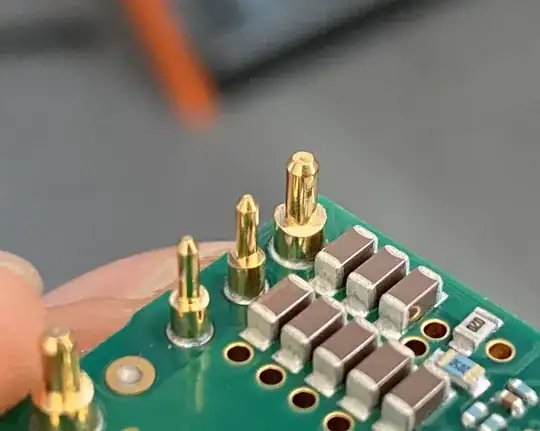

I am struggling with soldering some pretty think gold plated DIA pins to one of my boards.

I've tried various things such as;

- Increasing the heat of my soldering iron, but am afraid of burning my board.

- Sand off some of the gold plating to try and make the connection easier.

- Increase the amount of flux I use.

- Increase the time I'm heating the pin/board.

None of the above have given me favorable results. I'm hoping some of you here can steer me in the right direction.

I think I might be too careful and need to heat the pins/connection much more due to the heat dissipation of the thick pins, but before I do that and break things I want to check with some of you.

Thank you very much, I appreciate any responses.