Firstly, you're not going to get the motor to do much as it's configured at the moment. There are places on the terminal block for an external power supply, that will by default also power the Arduino through the Vin pin in the header - which is connected to the power jack on the Arduino board - there's a Vin cut-to-disconnect pad on the underside of the board to allow higher voltage at the motor than the Arduino likes. You can in theory power the motor shield from the Arduino's power jack, so long as the current and voltage aren't that high. What you can't do is power it from the USB socket - there's a regulator between the USB power line and the Vin line.

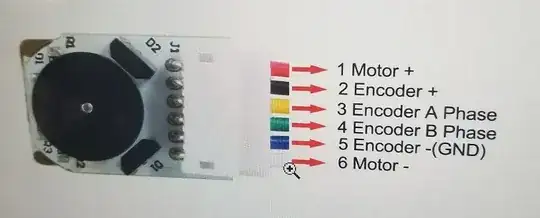

To use this as a servo, with control on position, you need to be monitoring the encoder, and count pulses that correspond to the rotation of the shaft. With the 150:1 gearbox and the encoder producing 7 pulses per revolution of the motor, you get one pulse per .34 degrees, or 1050 pulses per revolution. There are two channels in quadrature, so you can detect direction, but that probably isn't important for this, since the rotation is going to be determined by the polarity of the applied voltage on the motor.

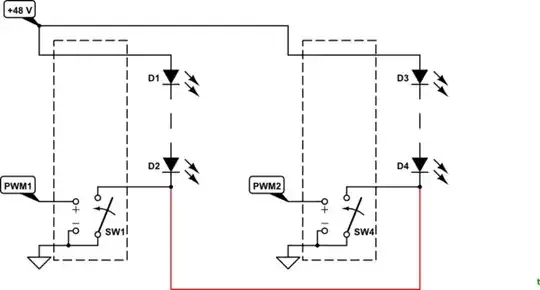

Since this is a DC motor, applying voltage across the brushes will give continuous rotation, at a speed roughly proportional to the voltage - so if you know that you need to rotate through a specific angle, and count pulses, then cut power to the motor, it'll overshoot, so then you need to put in some deceleration, achieved by ramping down the PWM as you approach the target position.

Arduino's default PWM frequency is only about 500Hz, it'll work with a DC motor, but be annoyingly buzzy, and that reflects in torque pulsations on the shaft, that'll cause gear chatter. There are libraries that allow use of higher frequencies. I'm not sure if you'll find any sketches written for this particular use, but you may find something similar that you can use as a start.

And finally - why are you using cheesy hardware like this for a space application? Brushed motors aren't even used in aviation - the lack of air and especially the water vapor means that the ionized gas layer that is under a lot of the brush surface isn't present to carry current, and the chemistry isn't there to deposit the film on the commutator, so it'll wear very rapidly. Or is this just a demonstration of the principle?