I need to charge my 60 Ah LiFePO4 battery with a small charger as fast as possible at 14.4V. There are lots of relatively cheap SMPS in the market which are not designed for this purpose (they are constant voltage supplies with overcurrent protection), so they are either failing to charge the battery or eventually burnt out.

The battery requires 45A @14.4V when it's fully discharged. It quickly drops to 30A after 10% SOC and maintains this current till 80% SOC. After that point, required current quickly drops and charging operation is finished.

I'm not able to place a sufficient power source that can handle that worst case current (40A) because of the space constraints. Moreover, it's not that wise to invest (and carry around) an additional 10A of hardware which will be only used for the first 10% SOC.

The SMPS' that have less than 40A @14.4V power rating is unable to charge this battery because all of them has "hiccup protection mode", which turns off the power supply on an overcurrent situation.

It turns out that the mentioned overcurrent protection somehow fails to operate correctly. I have burnt out 4 power supplies (360W to 480W) in one month. On the other hand, some SMPS models claim to have the appropriate current limit function but those have very insane amount of price.

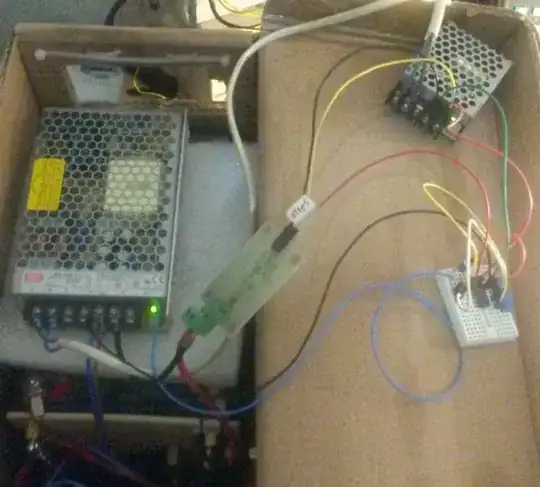

In this desperate situation, I'm planning to limit the output current while keeping the maximum voltage set to 14.4V, thereby limiting the output power to 90% (eg.) of the rated power of the supply. Moreover, as I'm changing the voltage/current characteristics of the supply as follows:

I'll be able to connect many of this modified SMPS' in parallel to get higher current without worrying the strict voltage matching requirements.

Current approach

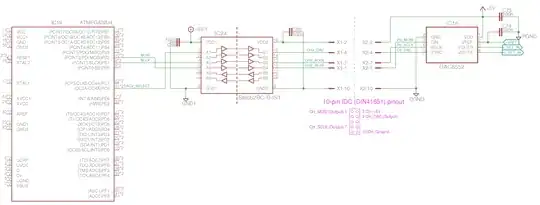

After some experiments, I figured out that the 2 out of the 3 pins of the variable resistor is connected to GND. :

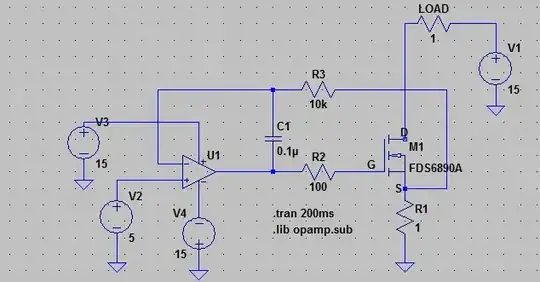

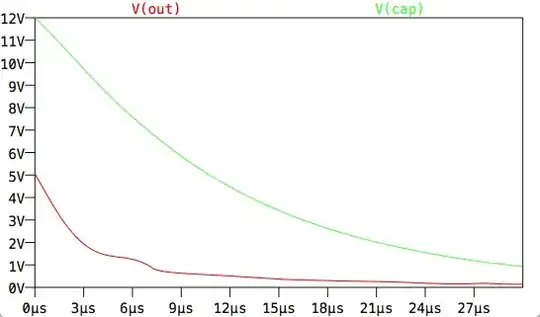

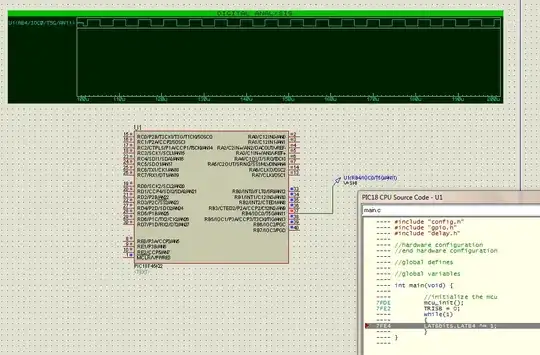

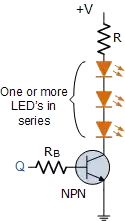

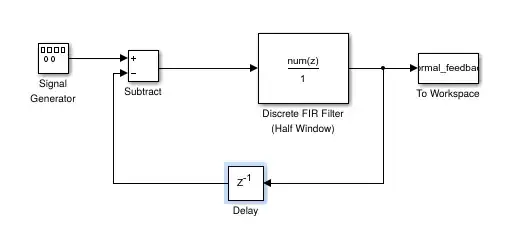

The other pin of the resistor has 0.96V while the output is 9.75V and 0V while the output is 14.3V. I'm planning to measure the output current and manipulate this reference voltage accordingly with the following approach:

- Set this reference voltage to the highest value by using that variable resistor.

- The SMPS will output its lowest voltage at this time.

- Add some voltage to that pin if the current is inside the limits till output voltage is below the required level.

Is there any easier way to achieve the same/similar result?

Edit 1

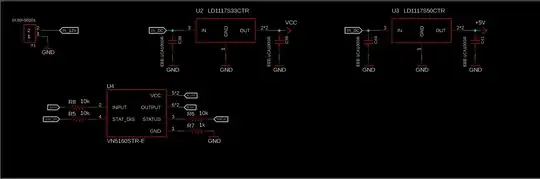

As I reverse engineered the feedback stage, there is AZ431-B reference diode used within the circuit and interestingly, the circuit diagram is the same as one of the examples in the application notes in AZ431-B datasheet: