I'm currently designing a 555 timer to provide a 38kHz square wave to drive an IR LED as part of a beam interrupt detection system.

This beam interrupt is a part of an embedded product where we cannot easily modify the existing processor software, and do not want to add a second MCU with a separate software installation step just to spit out a 38kHz signal.

The goal is to use the VSOP38338 as the receiver, so 38kHz +/- 2kHz should be sufficient for this application.

I am having trouble getting the output frequency of the 555 to match the calculated value I expect. Here are some value combinations I've tried so far:

R48 R49 C11 Fcalc Fobs

1k 191k 100pF 37.67kHz 31.4kHz

150ohm 1.82k 10nF 38.07kHz 31.9kHz

10k 10k 10nF 4.81kHz 4.68kHz

1.82k 1.82k 10nF 26.43kHz 23.5kHz

Regardless of the R/C combinations I've tried, the output appears to be significantly off from what I would expect. For reference, the resistors are 1% tolerance and the capacitors are 5% tolerance. The specific 555 chips I ordered are from Texas Instruments and all of these parts were ordered new within the last 3 weeks. I have verified the resistor and capacitor values with a multimeter out of circuit before installation. Also note that there is not currently an IR LED plugged in to connector J4.

Am I missing something obvious? I would expect some amount of variation due to the part tolerances, but the deviation seems unusually large.

I have tried replacing individual Rs and Cs as well as replacing the 555 chip itself. This has not led to any noticeable performance changes.

I have noticed that most examples decouple Pin 5, CONT, to GND with a 0.01uF cap. I am using an 0.1uF cap instead, because it was already on my BOM. As this is a decoupling cap, I didn't think going a bit bigger would make a difference.

Any suggestions on what might be causing the high level of frequency error?

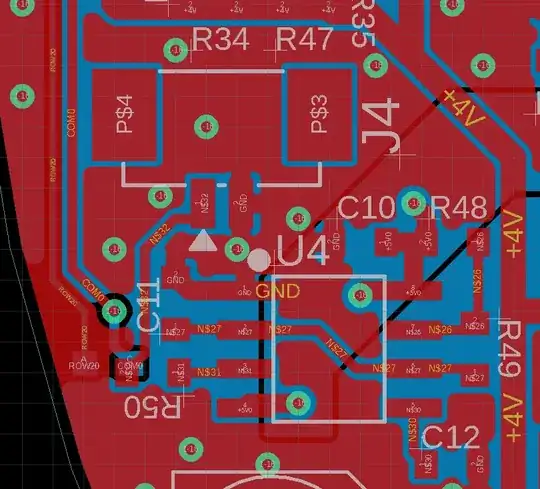

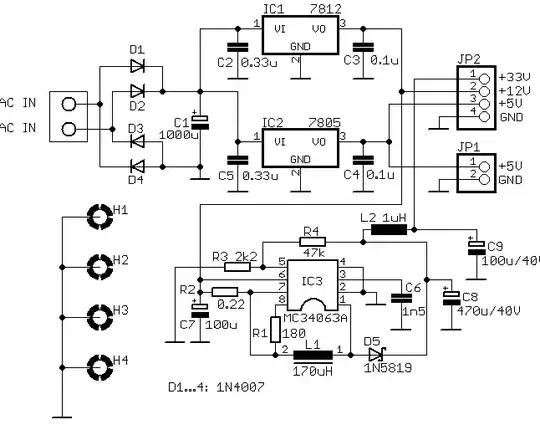

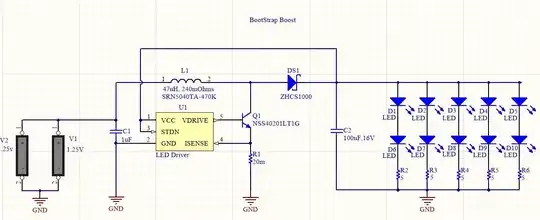

Here is my schematic and layout for the 555 timer:

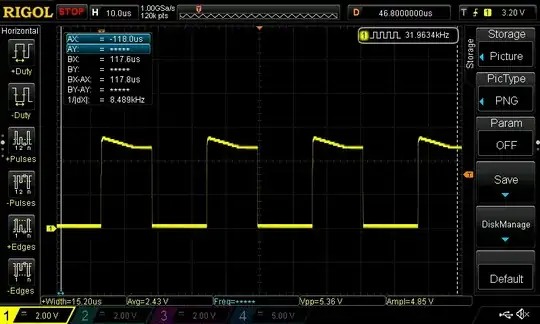

Here is an oscilloscope capture for the first arrangement, with the 100pF capacitor:

And here is an oscilloscope capture for the second arrangement, with the 10nF capacitor: