When inspecting the boards from electronics made in 1980s and earlier, one distinct feature is the extensive use of axial, electrolytic capacitors as power supply filter. Axial ceramic decoupling capacitors were used as well, to a lesser extent.

For example, this is a C64 motherboard.

Source: Wikimedia Common, by Gona.eu, license: CC BY-SA 3.0

This is a Tektronix 1720 vectorscope board.

Source: Flickr, by Toby Thain, license: CC BY-NC 2.0

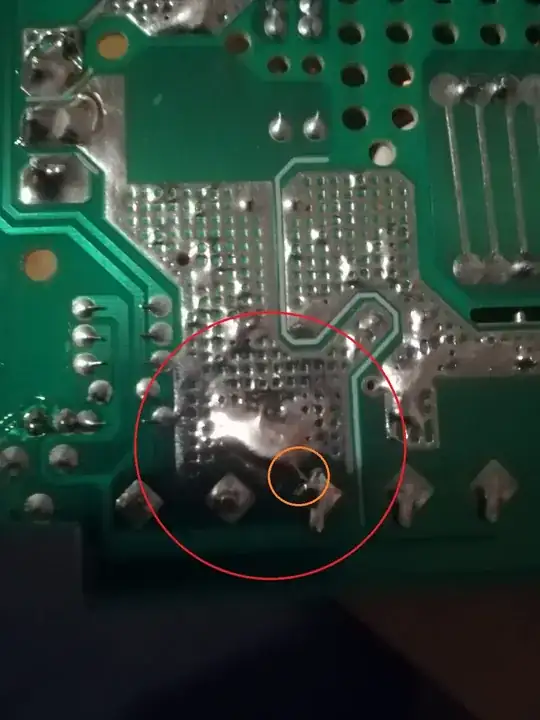

However, although they are still being manufactured, it seems that axial capacitors largely disappeared in most devices since the 90s. Almost none of electronic devices we commonly see have a single axial capacitor. And it's certain that one is going to find something similar to this in a modern device...

Source: Wikimedia Common, by Dave Jones from Australia, license: CC BY 2.0

Source: Wikimedia Common, by Dave Jones from Australia, license: CC BY 2.0

Question

Why did Axial Capacitors Fall Out of Use in the Industry? I can imagine that axial capacitors were optimized for point-to-point wiring back in the pre-PCB era, not PCB assembly, and that the introduction of SMT was another shot. But it was just my imagination, backed by nothing. What were the exact sequence of events and/or rationale that led to the disuse of axial capacitors?