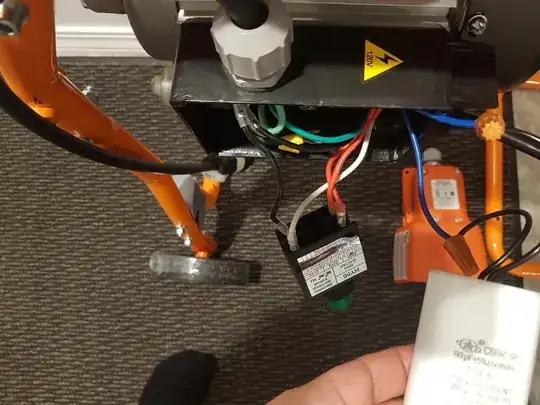

Good day. I have a 5 ton Yardmax electric wood splitter that I would like to add a single pole foot pedal switch. Right know there is a Kedu HY56 switch built in. The motor has 4 wires (2 blue, 2 red). The blue wires are hooked up to a capacitor. The red wires go to one side of the switch (there is straight continuity between these). The line wire goes through a reset switch before the push button switch. The common goes straight to the switch.

Can I wire a single pole switch to this, and, if so, how?

- 151

- 1

- 3

- 12

- 67

- 1

- 2

-

If you have an ohmmeter/voltmeter, work out a schematic and post it here. That picture and your few words are insufficient. And this ***is*** a dangerous piece of equipment. – jonk Nov 29 '19 at 04:24

-

18These tools don't have footswitches for a reason. If you enjoy having fingers, I strongly suggest you reconsider this. I know seasoned guys who have done wood their entire lives and have lost fingers to these tools by trying to go too fast and *cheating the safety systems* that force you to get your hands away from the blade. This is a **dangerous** way to work and it will make you pay with digits eventually. – J... Nov 29 '19 at 13:00

-

5Upvoted for asking instead of just doing it, to give people a chance to tell you this is a bad idea in general. – Peter Cordes Nov 29 '19 at 21:02

-

Can you? Yes. Should you? Almost certainly no, for reasons given by others. – Hearth Dec 03 '19 at 03:18

2 Answers

"THIS MACHINE KILLS"

WHAT YOU ARE TRYING TO DO HAS "ISSUES" EVEN WHEN DONE "PROPERLY.

Here I've copied material from two comments by J:

From the manual : For your safety, your log splitter is equipped with a “ZHB” control system that requires both hands of the operator. The left hand controls the hydraulic control lever while the right hand controls the pushbutton switch. The log splitter will stop if the lever or pushbutton are released. Only after the lever and pushbutton are released will the log ram return to its starting position.

It's worth noting that either OP's splitter has a different HY56, OR the HY56 is installed with the red lever permanently depressed (ie: the green button is a momentary switch, not latching). This switch is a safety switch whose only purpose is to force your hand to not be between the log and the splitting blade while you're working the hydraulic lever.

The HY56

Is a double pole single throw switch - it has a contact in both mains leads so the equipment is fully isolated when the switch is off.

Latches on when the green button is pressed and "trips" off when the red button or associated larger red lever are pressed.

It is not safely sensible to wire a single pole external switch to it as

You only switch one of the two poles.

This eitherwill not turn the equipment on or

needs one of the two poles in the HY56 to be bridged.

This would be stupid lethal and probably illegal.

You could use a two pole 4 wire foot switch with each external switch bridging one of the internal poles. This has potential safety issues as the internal and external switches can turn the equipment on. Depending on circumstance it may not be possible to turn the equipment off in an emergency. eg if foot switch is latching or if non latching and a log or user falls on it and holds it activated it the internal safety switch would not function.

If turned on with the internal switch and the external switch is held activated the internal cutout will work as intended but the equipment will not stop.

While confused internal / external interaction may only take a second or so to sort out, lives and limbs can be lost sooner than that.

The switch paths cross the switch "sideways" - not end to end. There is enough on the web re how the switch is wired that I am NOT going to expand on that or provide a diagram. If you cannot work out and implement with certainty a failsafe way of doing things from what I have written then you should be seeking help 'in the flesh' from an accomplished practitioner.

A second external HY56 with an external/internal changeover switch would deal with some but not all of the above issues.

A second external HY56 wired in parallel with the existing switch would be a mind-confusing man-trap waiting to maim or kill you.

- 147,325

- 18

- 210

- 386

-

It's worth noting that either OP's splitter has a different HY56, OR the HY56 is installed with the red lever permanently depressed (ie: the green button is a **momentary** switch, not **latching**). This switch is a safety switch whose only purpose is to force your hand to *not* be between the log and the splitting blade while you're working the hydraulic lever. – J... Dec 02 '19 at 21:41

-

From the manual : `For your safety, your log splitter is equipped with a “ZHB” control system that requires both hands of the operator. The left hand controls the hydraulic control lever while the right hand controls the pushbutton switch. The log splitter will stop if the lever or pushbutton are released. Only after the lever and pushbutton are released will the log ram return to its starting position.` – J... Dec 02 '19 at 21:42

-

1@J... Thanks - I've copied your comments to the top of the answer !!! – Russell McMahon Dec 03 '19 at 03:15

If safety is of any concern, than NO you cannot use a single pole switch. Your current switch is a four-connection AC switch.

This datasheets has a wiring diagram for a similar switch I used in a recent project: http://cdn0.grizzly.com/manuals/h8243_m.pdf

The AC source is likely connected to a driver board or internal rectification inside your motor, if brushed. I wouldn’t know for sure though, as it is not clearly pictured in your photo.

When switching AC signals on and off, it is electrical standard to cut BOTH the live and neutral wire’s electrical connection. This is because the neutral wire is said to become ‘energized’ when heavily loaded and can pose a risk of electric shock, and should NOT be thought of as a ground wire. However, if you are looking to shy away from standards, you could use your single pole foot pedal, so long as it meets the specs. Just wire the neutral wire straight to the motor connection and wire the pedal across the live wire. Once again, NOT RECOMMENDED.

Depending on your pedal’s construction, you may be able to modify it (I have done this before to save cash; some cutting will be required) and make it into a DPST switch for AC like the one you have already.

If you have a DC motor and can identify the rectified supply, a better idea would be to use some high power MOSFETs, and use your single pole foot pedal to switch the gates. Use P-Channel FETs so you don’t disrupt the ground return, and pull all the gates up to the supply voltage with a 50-100k resistor. Wire a 12-20v zenor diode between the supply and your gates, then wire your switch and a 50-100k resistor in series from the gate to ground. Your MOSFETs will spend some time in the linear region, but you are not switching them fast, so this should be of little concern. If they get hot, add more MOSFETs in parallel to divide up the current. You should leave your AC switch as well. Use this to turn the power on and off, and your foot pedal to start the motor.

One more quick note: I am not sure what type of splitter you have (once again more photos would help) but if you think you will always save power with your foot pedal instead of having the splitter constantly running with that pesky power switch, think again. If your downtime intervals are short enough, you can end up using more power that constantly running the splitter, as the Back-EMF generated from your motor has to rise up every time you restart it. The restarts thus use more power by far than normal operation. For large motors with medium idle loads, reaching full speed could take several seconds. If your motor draws 8x the current on average over the first two seconds at start up, you are dissipating 64x the power! Two seconds of this could use more energy than a whole minute of uninterrupted running doing nothing at all!

- 886

- 6

- 22

-

4`but if you think you will always save power with your foot pedal` - it's not about saving power. The button on splitters is deliberately placed far from the splitting wedge to force you to hold it down as a 'deadman' switch while you operate the lever to run the hydraulics. What OP is trying to do is to move the deadman switch to a foot pedal so that it frees up a hand to move the wood through while needing only one hand to operate the hydraulics - ie : to defeat the purpose of the deadman switch, which is needless to say, very dangerous. Unless OP is already missing a hand or arm, of course. – J... Nov 29 '19 at 21:47

-

1The other way to defeat the switch is to work in a team of two - one person loading/unloading the splitter and the other running the hydraulics. If you've known anyone who has worked with splitters this way, you probably also know someone who has lost fingers because of it. – J... Nov 29 '19 at 21:50

-

2