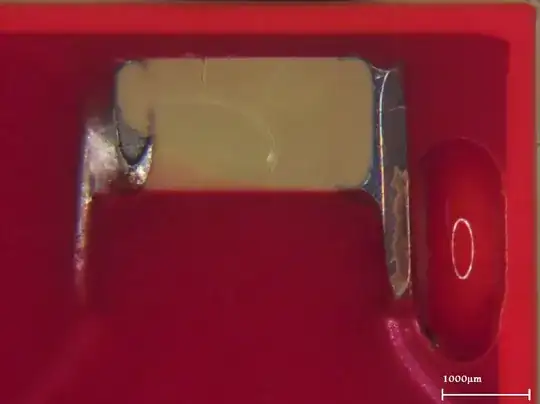

During testing, a capacitor was found to cause an intermittent failure - going short circuit when heated.

The capacitor style is a through hole, radial lead, CECC rated 68nF MLCC. Our supplier makes these in small batches, so we assume they buy in SMT capacitors, solder leads + encapsulate them. It is not known if this is an automated process.

During sectioning, it is shown that there are significant cracks across the surface. Xray reveals these cracks are deep.

Question: What conclusions can be drawn from this analysis?