I have a problem with perfboard, every time I made a circuit which works flawlessly in breadboard, doesn't work on perfboard. Is it because of soldering distance or am I doing something wrong?

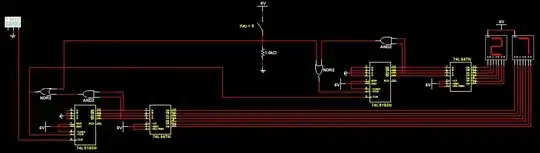

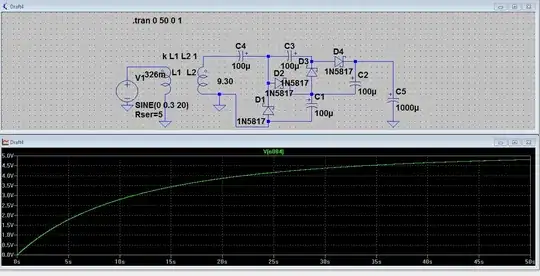

All circuits are 5-12V and low current (200mA max). First one is 7 segment display, second one pwm motor control, last one Ne555 frequency generator. Display circuit's problem is display randomly flickers segment. PWM's problem is MOSFET randomly opening or closing (and heats up). NE555 problem is output is always on even NE555 removed.

It seems like solder or perfboard causing the voltage jump (somehow) but I checked several times and multimeter shows no connectivity, I tried to clean the paste and clean the space between solders but still no luck. Some of my circuits to show the problem: