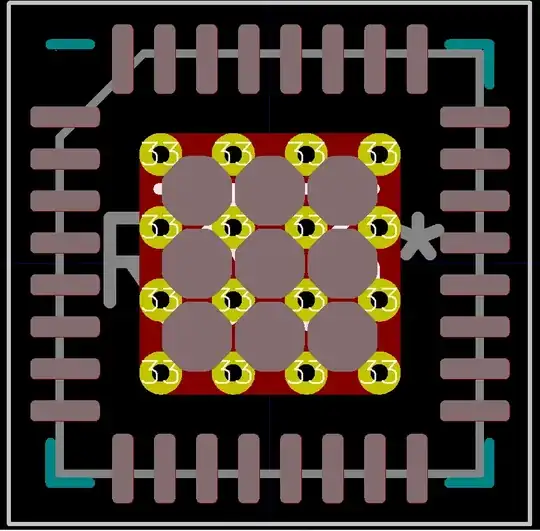

I have this footprint from the KI-CAD footprint library (LFCSP-32-1EP_5x5mm_P0.5mm_EP3.1x3.1mm_ThermalVias).

The paste-mask shows several circular paste areas under the thermal pad. The separation between the paste areas is only 1-mil.

The areas between the paste circles in this paste mask would need to be entirely supported by 1-mil thick strips of metal.

If the stencil could even be manufactured using the usual methods, I seems that it would be exceptionally prone to breaking in that spot. It seems to me that it would be better if the paste circle diameter was reduced by 5 to 10 mils.

Is it possible to manufacture a stencil for this paste-mask using typical stencil making methods?