I have a set of LED driving lights on my motorcycle that must be wired through a ground-leg pulse width modulation dimmer. The problem is the mounting bracket for the lights is grounded, so the lamp shorts to ground through the motorcycle chassis and the PWM dimmer cant dim the lamps. I had solved this issue by isolating the lamps from the motorcycle's chassis at the mounting point, but this has proved unreliable in the rain, and the brackets I had to use weren't up to the task and eventually broke.

I now need to look at internally isolating the lamp housing from the ground leg of the circuit. I had hoped that when I opened up the lamp there would be a separate grounding lead screwed to the light housing that i could simply disconnect, but it appears that the housing is grounded simply by the contact between the PCB and the housing, plus the PCB mounting screws.

My first thought was to just put some small rubber o-rings between the PCB and the housing, and switch from steel to nylon screws for mounting the PCB, but then I remembered that the LEDs need a thermally conductive path to the housing for cooling.

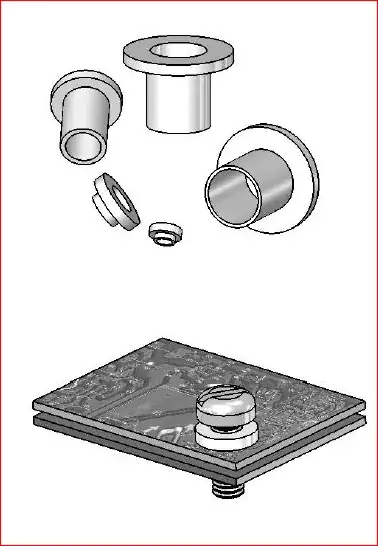

So the question: how to provide a thermally-conductive, electrically-insulated mount for this PCB?

I've seen mention of mica washers, some mention of electrically-insulating heatsink compound, but nothing that seemed authoritative enough to scream "answer."

The PCB is probably 7cm square, and it is surface-mounted to the lamp housing/heat sink by 4 screws, one at each corner. The PCB's entire back appears to be aluminum--actually it looks more like the PCB is aluminum. More likely there is a very thin PCB laminated onto a piece of aluminum stock, pretty cool really, first I've seen like that.