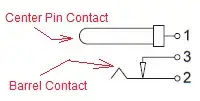

I am going to use TZC3 family trimmer capacitors from Murata (datasheet, skip to TZC3 section).

It has one of its terminals very close to the mounting surface, and theoretically if rotor is pressed too much (or device is overheated during soldering causing damage to the body), body can be bent and it potentially causes shortage of the rotor with the tracks on the surface of PCB underneath. No clearance size value is given in datsheets (I have no real device on hand to measure).

There're a number of slightly varying datasheets available on the internet, none of them mention that area underneath must be restricted.

Do I bother about it too much, or risk is real?

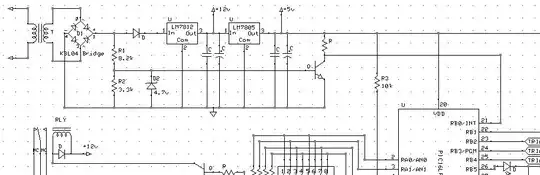

While writing this question I have got an idea to simply extend the track connecting to the rotor terminal to the central point of the device PCB area so that if issue happens, it shorts to the same signal. But one of the capacitors in my design is having power rail under it, and it seems I will have to divert it out of the area.

Update:

Following Finbarr's comment I did the following layout:

removing ground potential in proximity with the bottom knob.