When soldering headers, usually single and double pins, I flip the board over so the pin rests on the surface and then solder them. They never come out straight. It would be great if someone has figured out how to do this correctly?

5 Answers

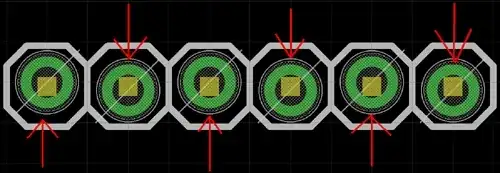

If these are boards that you are designing, then is there something you can do to make it easier to solder header on straight. If you stagger the holes like this:

(image and concept from SparkFun)

...then the header will essentially lock into place when you insert it. Doing it this way, you probably won't even need any special soldering techniques.

If you're using Eagle, SparkFun's library has many pin header footprints that "lock" like shown.

- 2,151

- 1

- 24

- 32

-

3That is pretty cool. – Bill Oct 23 '12 at 00:14

-

1That is really really cool. I might to that on my next batches see how well it works +1 – Piotr Kula Oct 23 '12 at 14:34

-

Your solution is very good. I am going to try Scott's idea in the short term and your idea in the long term. – Bill Oct 23 '12 at 17:02

-

1Very clever. Next time, I will make my own PCB library for headers, I will design the holes like in this design. – hkBattousai Oct 25 '12 at 19:37

-

1Offset headers are bloody amazing. – Passerby Jul 28 '13 at 09:31

-

And some day we will see a new question on EE/SO: "Staggered holes in a PCB??" – gbarry Jul 09 '14 at 05:23

Solder ONE PIN. Reheat the solder while pushing down to make sure the element is flat. When convinced, solder the rest of the pins. As a last step, reheat the original joint just to make sure it wasn't moving as it cooled, which is a bad thing for a solder joint. This technique works equally well for through holes and SMT.

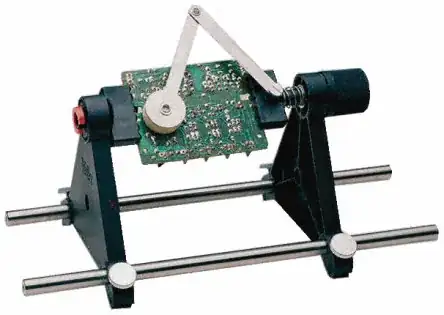

I've used a PCB cradle with a foam cushioned arm that works pretty well. You can hold down elements and then rotate the board.

- 29,274

- 4

- 44

- 109

-

7Yup, was just about to say that. When soldering one-offs, I only solder one pin. Then I hold the board in one hand, put my finger on the header (NOT ON THE PIN YOU WILL BE SOLDERING, LOL, IT BURNS). With your free hand, grab the iron and hit the solder again and when it melts, push the header to the desired orientation. Then finish the job. – dext0rb Oct 22 '12 at 22:23

-

-

stick the pin on a cardboard box or some play-doh, that will hold it straight while you solder it – Kvegaoro Oct 22 '12 at 22:36

-

8@BSEE When soldering a single pin header you should not hold the header yourself. Get a friend to hold it. Otherwise you will burn yourself. Even then, there are some parts that are very hard to solder "straight". If straightness is required then just don't use those parts. – Oct 22 '12 at 22:37

-

@BSEE - The technique for the one pin header is similar. You solder just one pin and then use a pair of tweezers to hold and steer the pin into position when you hit the pin again with the soldering iron. It can be very helpfil in this scenario to have the board clamped in an electronics bench vice. – Michael Karas Oct 22 '12 at 22:40

-

When difficult, pliers and a good PCB vise can do wonders. I've seen PCB holders with a sponge-like thing on a moving arm to hold down components -- http://shop.rabtron.co.za/catalog/images/Weller%20Soldering%20-%20Weller%20PCB%20holder%20ESF130.jpg -- I'd avoid those silly "third hand" things with alligator clips like the plague, though – Scott Seidman Oct 22 '12 at 22:45

-

7@DavidKessner I agree, burning a friend is better than burning yourself :-) I guess OP should make sure he has a good supply of friends on hand first ... – user207421 Oct 22 '12 at 22:55

-

-

1@BSEE http://www.testequipmentdepot.com/weller/accessories/holders.htm – Scott Seidman Oct 23 '12 at 00:21

-

1

-

@Scott the "Helping Hands" things aren't that great for holding PCB's (I recommend Panavise Jr), but they are actually pretty decent for holding a through-hole part onto an upside-down PCB for soldering. – JYelton Dec 12 '12 at 23:57

If I'm soldering parallel rows of headers, I'll often put the headers into a solderless breadboard and put the board on top, and then solder the pins. The breadboard keeps the headers nice and straight during soldering.

- 4,650

- 10

- 48

- 53

-

Great idea! I can see it breaking down on larger boards that would have headers on the outside unfortunately. Still hard to keep everything straight when the weight of the PCB is throwing things off. – Kris Bahnsen Oct 23 '12 at 20:43

-

-

2Not a bad idea (I always use the "solder one, reflow to align, then solder the rest" methodology) but make sure for your idea to use OLD breadboards... heating will melt the internal plastic and tend to make the breadboards... funny. At least funnier than a new breadboard. :-) – akohlsmith Oct 24 '12 at 03:43

I have a few techniques that I use from time to time:

- Solder one pin while holding the opposite end. Reheat the solder and straighten.

- Use painters or masking tape to hold the pins in place, especially when the pins aren't on the board edge. Again, solder one pin, then straighten as needed.

- If you have the PCB in a vise or "helping hands", use another helping hands to hold the pins in place. Depending on your setup, you can solder the pins in straight with no further adjustment (check before you solder additional pins).

- If you're soldering a lot of something to a board, and making multiple boards, it may be worth your time to make a jig. I do this for LED's as well as various connectors/headers. The jig can be wood or plastic (beware of ESD, though). I use a drill press to make holes of the correct depth. Populate the board with the headers, place the jig over it to hold the pins/LEDs and then turn the whole thing over. The jig will hold the PCB in place as well as keep components straight. This depends quite a bit on your board design, so your mileage may vary.

- 32,302

- 33

- 134

- 249

I fix components (one at a time) with school putty (the white putty that leaves no marks) before soldering. WOrks very well.

- 91

- 3

-

3A link to the kind of putty would be useful, not everyone know what kind of putty you used in school :) – Trygve Laugstøl Oct 24 '12 at 10:26

-

I believe the longer description for it is "[Duck Brand Removable Reusable Non-Toxic Poster Putty](http://www.amazon.com/Removable-Reusable-Non-Toxic-Poster-Putty/dp/B000BQMFEC)" [(Mfg Site)](http://www.duckbrand.com/Products/craft-mounting-products/mounting-products/poster-putty.aspx) – JYelton Dec 13 '12 at 06:34