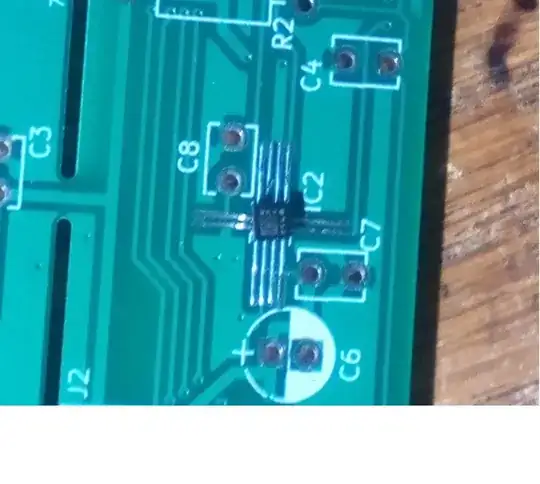

This is a 2 x 2 mm chip with 12 no lead contact points. Half of the time I get it out of the reflow oven, it's twisted like in the image below.

I am using a stencil in order to lay the paste down and then tweezers for placing the little chips. There is no fan in the oven and I let the boards drop to < 170 C (leaded solder paste) before pulling them out. There are also some even smaller 0603 parts which never twist / tombstone.

How do they become crooked, and what can I do in order to avoid it ?