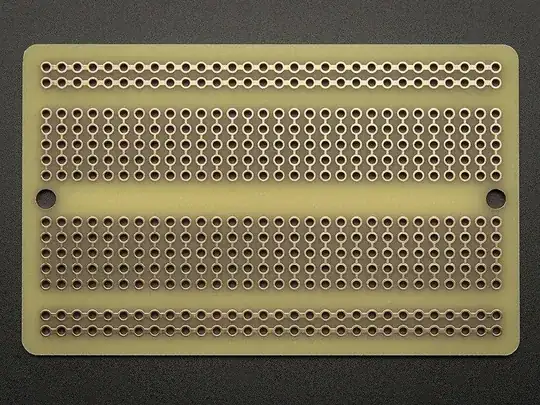

A perfboard is not like a breadboard. A perfboard is called so, because it has holes in it, it is perforated!

So the whole perfboard contains only holes and no connections between any holes (unlike the breadboard). You have to interconnect the holes yourself.

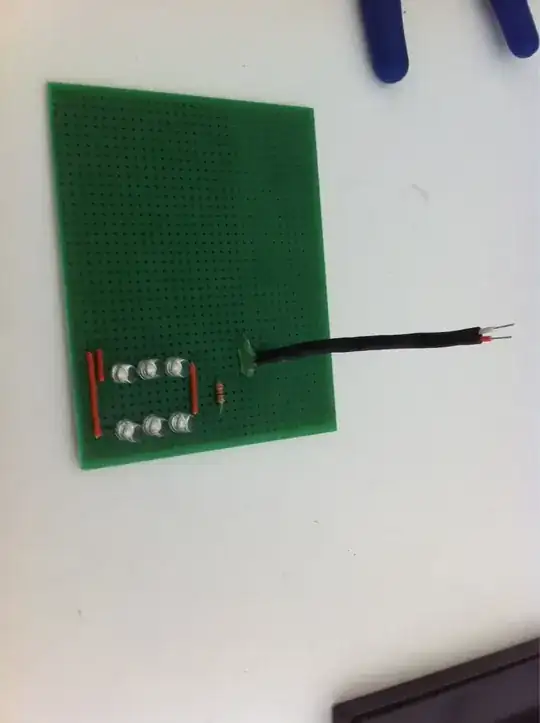

In this case, you have to connect the two leads of the resistor to two jumpers. The first step is to solder every individual component on the perfboard. You did this step correctly!

Second step is to make connections between the soldered leads. In this case, you have soldered two resistor leads and two jumper leads. To connect leads together, you have to solder another wire between them, or you can just use a solder joint between them, i.e., connect the two leads only using solder.

The purple lines represent the connections you should make, i.e., the wires you should place externally to connect the required perfboard pads:

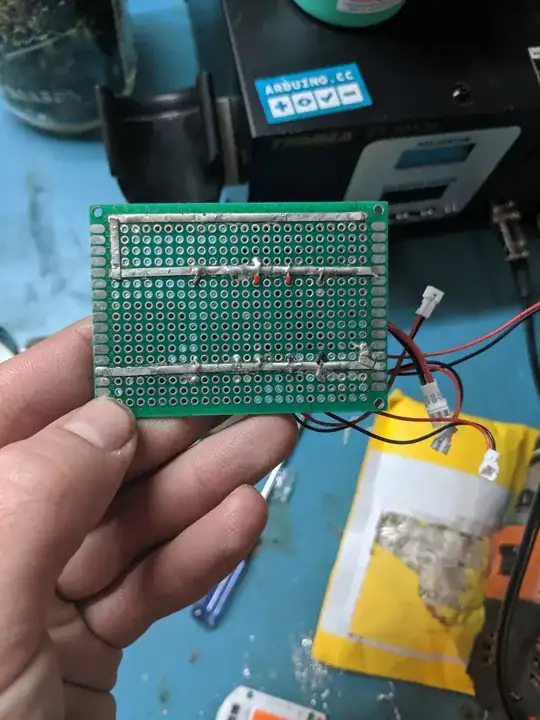

This is how you can connect adjacent holes using solder bridges. Source: How to make traces on an universal PCB?. Look at the answer by JYelton.

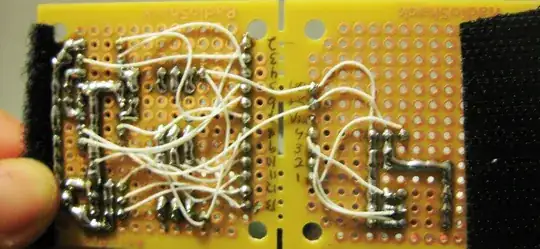

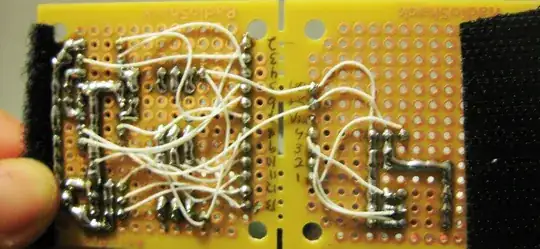

Also, you can use wires to solder holes together like this - Source: How to make traces on an universal PCB?. Look at the answer by Passerby.