Good day, I am investigating the effects of varying stepping angles of a stepper motor on its power consumption. How does microstepping affect the power draw of stepper motors?

2 Answers

Microstepping has the effect of increasing stepper motor power consumption above what it can be under standard stepping conditions.

A stepper motor when used in the conventional one-step per physical position mode latches electro-magnetically. Two conditions apply.

i In the stable "home" position power may be removed and the motor will remain in that position unless perturbed with a torque in excess of the specified holding torque.

ii The user may elect to continue to apply voltage to the coils with the same polarity that caused it to step to the current position. This may be full stepping voltage or some reduced voltage. This applied voltage will increase the holding torque but also add to the power consumption

In microstepping the motor is held at some intermediate position between two "steps" by applying PWM to the windings in some ratio that on average holds the motor in an intermediate state. (With some coil arrangements it may be possible to apply two different analog voltages on two windings to maintain an intermediate position but this is (probably) less likely).

However it is achieved, holding an intermediate micro-step position requires holding the rotor dynamically between two potentially zero energy electromagnetically stable states.

So

At best, microstepping uses no less power than an arrangement where a holding voltage is applied to the windings when the stepper motor is in a stable "home" position.

Compared to situations where a stepper motor sits in a stable home position with no more reduced voltage applied the microstepping mode uses more energy. How much more depends on the ratio of stationary to stepping time used in the normal mode.

- 147,325

- 18

- 210

- 386

Assuming a common bi-phase stepper motor, it is going to use an H-bridge and PWMs to create target average currents on the coils. Without micro-stepping, only one coil will be energized at a time. With micro-stepping, two coils will often be energized at a time with a varying target current ratio. I believe that they are designed so that the total average current on the two coils is the same.

With perfect PWMs, I don't think that there would be a difference. Practically, there will be losses every time the PWM transistors switch. So rotational speed and the micro-stepping will probably affect the losses.

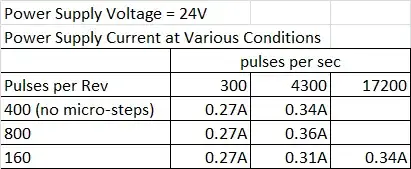

Edit: I am working on a Stepper Motor project, so I took some measurements. I am using a common Stepper Motor Controller I got from Amazon.

Micro-stepping doesn't seem to affect it much. Rotational speed is more of a factor. Note that torque on the motor does not affect the current.

- 13,638

- 1

- 19

- 43

-

note: the last pulses-per-rev should be 1600, not 160 – Mattman944 Apr 08 '19 at 14:01

-

I assume that that assumes holding current = stepping current at stationary points? What is the difference in hold torque with and without a coil activated? – Russell McMahon Apr 08 '19 at 17:31

-

Holding torque is much higher when the coil is activated. My motor has a 19:1 built in gear. With a small coupler attached, un-activated I can turn the shaft with my hand, with a little difficulty because of the gear. Activated, no way. I am hesitant to add a lever arm to see just how strong it is, I am worried I could damage the gears. – Mattman944 Apr 08 '19 at 18:46

-

The controller keeps the (short term average) current constant. The current doesn't change when torque is applied. – Mattman944 Apr 08 '19 at 19:36

-

Are you saying that the current constancy is a controller function and not an attribute of the std or uStep methods per se? || Long long ago I built a microstepping system to control the movement of a pointer in a disability device. The "controller" was probably a ULN2803 [ :-) ] to give the overall microcontroller requisite drive power. Having a black box between the uC and stepper motor rather changes what is being asked and/or answered. No? – Russell McMahon Apr 09 '19 at 01:41

-

Yes, I am assuming that the OP will be using a COTS "black box" controller. They are very common now days, and if the OP was designing his own, I doubt that he would be asking this question. Stepper motors seemed to have evolved into a widely used common design (bi-phase windings, 400 steps per rev) in the last 30 years since I last used stepper motors. Based on my observations, a micro-step controller won't necessarily draw more power, although it will depend on the design, some may draw more. This still has me curious, I plan on scoping the motor signals sometime. – Mattman944 Apr 09 '19 at 02:33