Newbie 16 years old here.

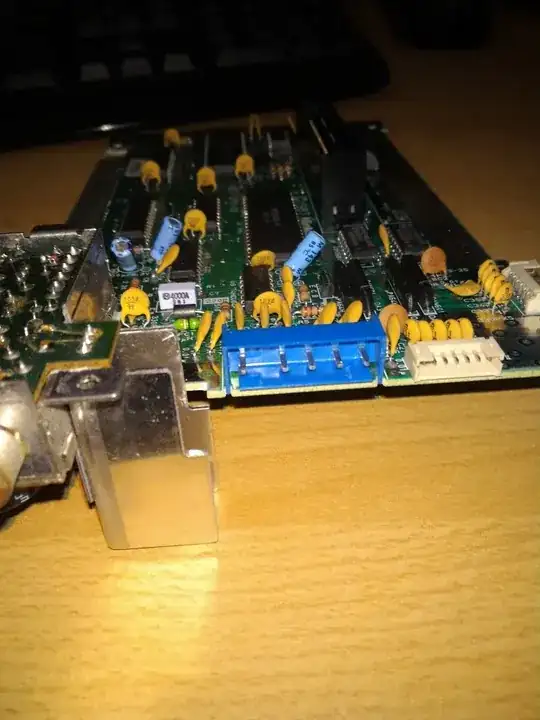

My project is a mini robot with the pcb as the chassis, lipo battery with charger circuit, and infrared sensors. I used LSM6DS33TR for my I2C accelerometer and gyroscope with 10K "pull-up resistor" according to datasheet, and ATMEGA328P as microcontroller.

It is my first time to design my own industrial PCB board and manufacture it. I manufactured the PCB's with JLCPCB. After sending the files and waiting for delivery, when i spot a mistake from my design. I noticed that I haven't wired the pull-up resistors for my I2C bus correctly because they should be pulled-up to 3V3.

My Questions are:

- How can I redirect connections or make modifications to make the SDA and SCL pull-up to supply voltage with PCB being manufactured already?

- Should I change the design and manufacture another PCB? (Broke ):)

Here is the entire schematic diagram for the project I made:

(the i2c lines are encircled)