A lightbulb (a plain old incandescent lamp) is typically brought up as an example of resistive load.

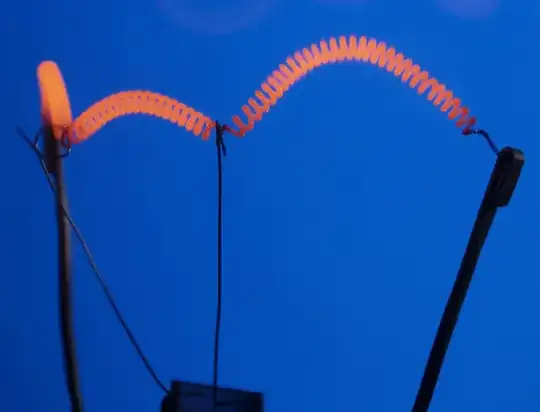

Yet the filament is actually made of several feet of very thin wire cleverly coiled to form a filament which is about one inch long. Clearly coiling the wire this way makes the filament more or less similar to an inductor. Yet lightbulbs are not considered inductive load.

Why are lightbulbs considered resistive load with a filament made of coiled wire?