Would I get a better lumen output and improved thermal characteristics

for the same wattage if I get a higher rated LED?

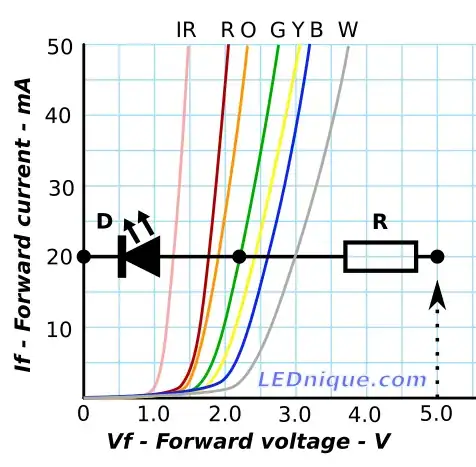

The cost of thermal management is high for CoBs. More and lower wattage LEDs are usually most efficient. Efficacy usually drops when you exceed the "test current".

What I do is implement the best thermal management I can do then adjust the current so the PCB temperature next to the LED is 40°-50°C.

One of the most important characteristics is the efficacy specified in Lumens/Watt. Higher efficacy means more light, less heat.

Cree LEDs and I'm confident that they are the best brand for me to go

with

Too general. Cree makes very good LEDs. Citizen, Samsumg, Lumileds, Luminus, and Bridgelux make very good LEDs also.

the most uniform and wide-angled light output

CoBs will have the least uniformity due to the high lumen density. They generally have the least lumen/watt efficacy.

A strip of LEDs will give best uniformity. Mid-power LEDs have the best efficacy.

I am not well versed on LEDs for photography regarding CCT and CRI. I do know higher CRI is more natural. I mention this because the strips I would be interested in if I were looking for photography lighting are 90 CRI.

I am thinking that a variety of CCTs would be desirable. And a tunable CCT would be a big plus. Dial in the mood.

The Bridgelux Vesta Series Tunable White Linear Strips are very reasonably priced and versatile. Each strip has two rows of mid-powered LEDs. One row of 2700K and one row of 5000K. You can use two LED drivers, one for each row, and "tune" the CCT in any combination.

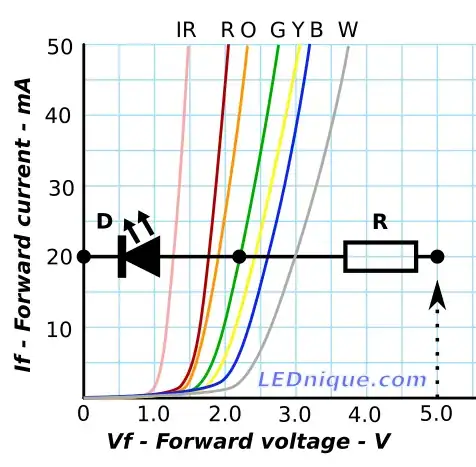

The higher CRI is difficult to achieve as it requires more red than most LEDs can produce. White LEDs use phosphor wavelength converters to convert 450 nm deep blue (near black light) to blue, green, yellow, orange and red. Red being the least efficient.

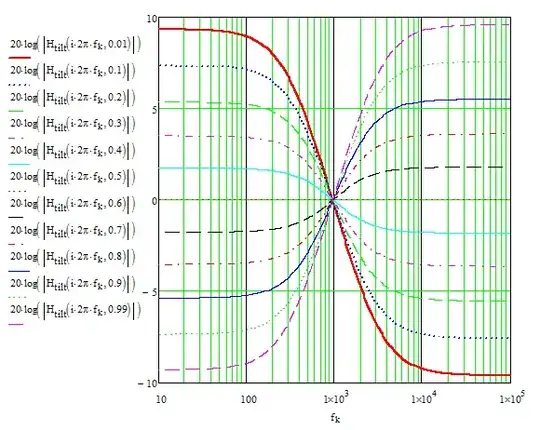

If we look at the spectrum for a 4000K we can see the amount of red and its peak wavelength.

Notice the "Premium Color" peak wavelength is 630 nm and the 90 CRI peak is about 615 nm. 615 nm is a red-orange.

Cree CMT1922

Notice the 2700K 90 CRI red peak is 630 nm.

Bridgelux Vesta

ARCTIC Alpine 11 Passive

Thermal Adhesive

With strips thermal management is much easier as the heat is distributed over a larger area and the efficacy is better. You would need a heatsink only if you were pushing both rows hard.

If I were to use a heatsink with these strips I'd use a $5 HeasinkUSA's 12.000" Wide Extruded Aluminum Heatsink cut to 1". I would apply it using the thinnest 3M thermal tape I could find.

Vesta vs. Cree CMT1922

500 mA vs. 600 mA

25V vs. 34V

24W vs. 20W

3272 lm vs. 2385 lm

136 vs. 116 lm/W

$5 vs. $8

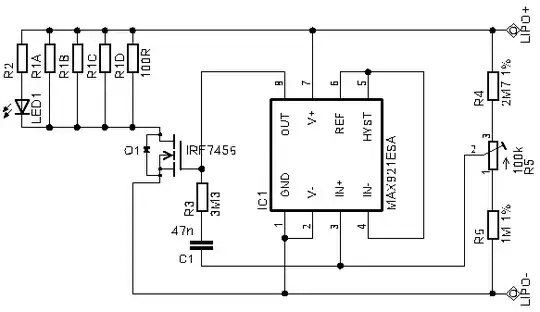

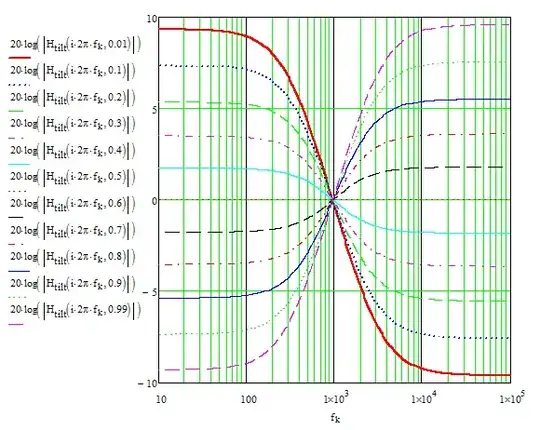

You need a high quality LED driver if you are going to use these for video. You need continuous conduction with low ripple current.

I would use two (one for 2700K and one for 5000K) Mean Well HLG-60H-C700B drivers (5% ripple current). I would drive two BXEB-TL-2750G-1000-A-13 in series.

I would mount the strips about 6-8 inches apart for best uniformity.

I used seven strips mounted on aluminum angle brackets.

I made a PCB for power distribution and use a dip switch to select currents. The Mean Well HGL type B can use resistors to set the current. I have a pot to fine tune.

CRI does make a difference