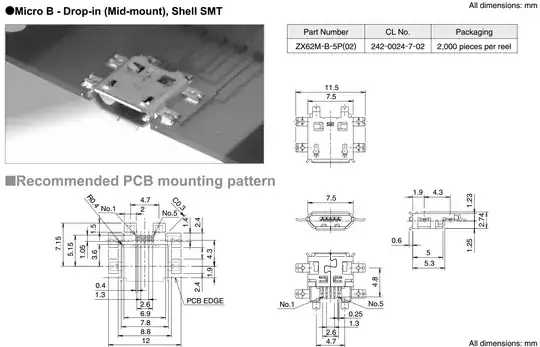

This USB micro B has 6 mounting tabs. If I ground none or only 1 of them, will it ruin the signal? There is a pad for the signal ground that is separate from the mounting tabs.

Fyi USB 2.0 has a max signal rate of 400 Mbps, and an effective payload throughput of up to 35 Mbps, according to Wikipedia.

Is there a general best practice for lazy / layout-confined people to decide how many mounting tabs have to be grounded for a tens-of-megabits connector?

If I only ground one of the tabs, should it be the one closest to the board edge (i.e. to the cable)?

Thanks!