Not sure if this is the right stack to ask this question on, but it relates to an engineering project that I and a student electrical engineer are starting.

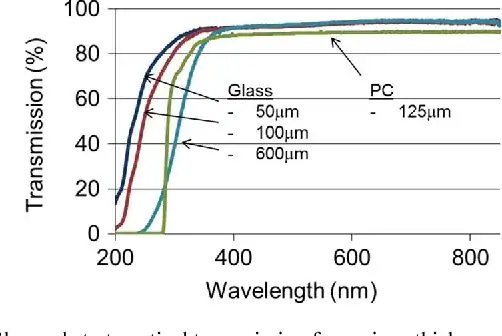

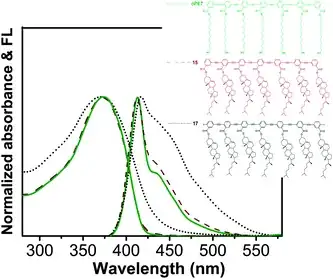

Can an LCD screen be used as a masking layer between a UV light and a photosensitive material?

I have looked at a lot of other options and this seems the simplest and cheapest. Because LCD screens are inexpensive, have a high resolution, and are easy to control (no spinning mirrors or mechanical parts). This only works if the LCD screen is capable of controlling where the UV back light is admitted on its surface.