The following is really the way to go if your repaired board needs to be as reliable as the original, and your customer's going to pay for it.

If one of these two requirements aren't met: Fly a wire for the broken connection, and solder your replacement IC to the intact ones.

(0. business experience: people trying things like these albeit lacking necessary skills to save money on repairs might be problematic with respect to finances. Communicate how high the invoice is going to be early. This will take two hours of design work even if you're extremely familiar with your PCB editor, or longer, if you need to figure out which pads need a decoupling capacitor close to it and you need to make a non-rectangular board. This will require about 4 hours of handiwork, unless things go surprisingly smooth on the first try. This requires ordering an SMD stencil and a thin PCB, and replacement IC. This requires a full functional test. So, invoice for no less than let's say 10 hours of work at whatever rate is comfortable to you.)

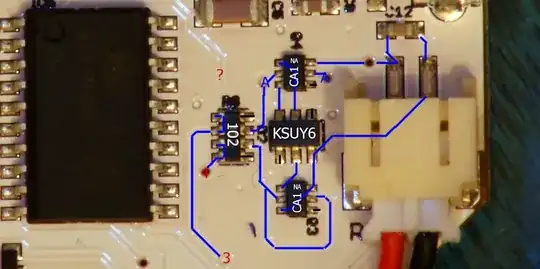

You'll have to make an adapter board, because lifted traces are virtually unfixable.

Cover adjacent components on the original PCB with Kapton tape. Use a hot air gun and carefulness to remove excess solder from all the pads and vias that you'll have to connect your adapter to. Keep the tape in place.

You should probably in the same step fill the empty vias that you will need to solder to later on with solder to avoid them sucking the solder away from the contact.

So, get your favourite schematic editor, and place the IC.

Make a modified footprint/component that has the same contact postions (but smaller) where there are undamaged pads on the original PCB, and a round pad for the next connecting via where there is a damaged pad.

Mirror that footprint, and put it on the bottom side of your adapter PCB design, the original IC footprint on top. Connect using vias as necessary.

It might make sense to make the adapter PCB a little larger (potentially not even rectangular, seeing that space is tight) than minimally necessary, and to place decoupling capacitors close to the IC on the topside.

Don't forget to a add a ground plane on both sides of the PCB. Extensively use ground plane via stitching. You'll need that for heat transfer during soldering the adapter on.

Print out the PCB design in real size, cut it out and verify it'll fit on the board, and actually hit all the right places.

Get that adapter PCB made, if possible, on thinner than-standard PCB substrate (oshpark has a very cheap and for your trace sizes sufficiently accurate 0.8mm PCB service).

Order a SMD stencil for the adapter board. Cut it so that it fits on the original board. Tape it in there. Use the stencil to apply solder paste to the original board. Carefully remove the tape that holds the stencil in place and lift of the stencil. Drop the adapter PCB into place.

Solder on using hot air (if possible, alternately heat from both sides). (that's why you taped the other components down, so that they don't get blown away).

Solder IC on top of adapter PCB as usual (for this specific footprint, you might not even need a stencil – a fine line of solder paste from a syringe across the pads might be sufficient).