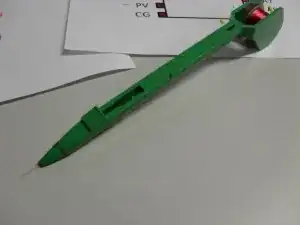

I'm using Verowire (wiring pencil, Road Runner, you name it) quite often to contact test points on my board to make them accessible for measurements (oscilloscope probe, multimeter clamp ...)

Image source: Not a number.

Every now and then it happens, that the insulation will not melt away and make soldering the verowire almost impossible.

I usually have to cut off a piece and start again - which seems odd as some people are creating artworks with Verowire.

What I usually do:

- Temperature 350-400 °C

- Blob of solder on the iron

- Insert the end of the Verowire into the blob (usually melts the insulation and tins the wire)

- Solder wire to test point

Any points which I'm doing blatantly wrong in that approach?