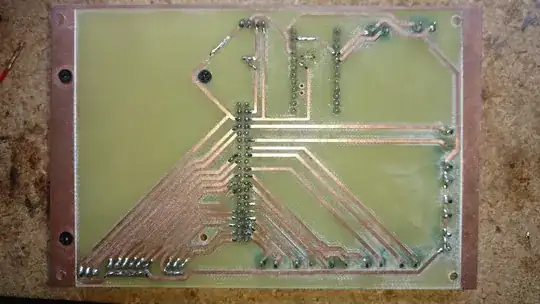

I am working with Arduino/raspberry Pi modules and trying to secure them to a Lego plate. Because of the soldering joints on the bottom, there isn't a flat surface to work with.

I have tried crazy glue which works. I also tried a sculpting clay which attempted to take care of the bumpy surface of the joints, but that didn't hold (the clay had crazy glue on both sides).

Even though the modules still worked, I would imagine that this introduces added resistance to the circuit where it wasn't intended.

It looks like standoffs are the best way to go, even though there is nothing readily available for this purpose.

I'm wondering if there are any other options to consider?