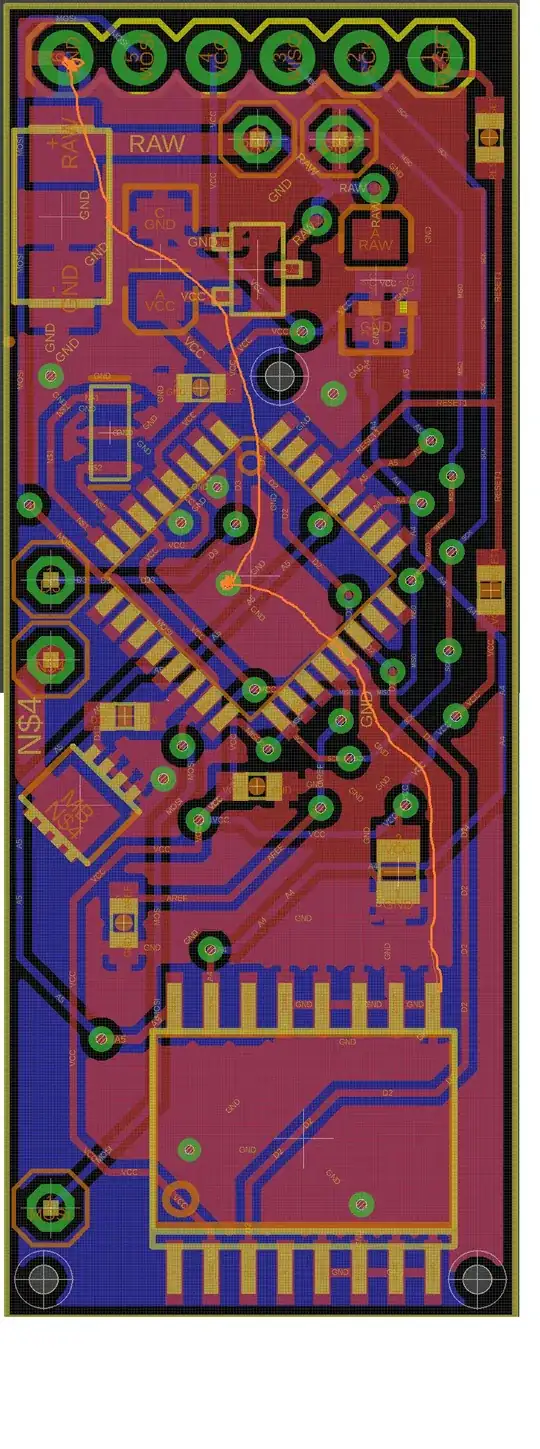

EDIT: After taking all what you guys said into account, I edited the pcb into the following. Changed the FTDI while breaking the ground loops and working on the traces a bit, changed the size of the 100uF capacitor and hopefully the new routing is better.Give me your thoughts over that

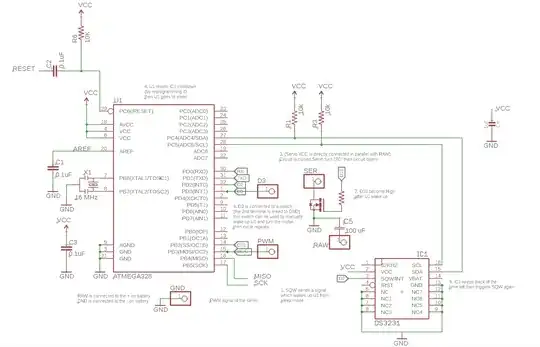

nearly identical circuit just added the ISP and removed FTDI

nearly identical circuit just added the ISP and removed FTDI

So I've drawn an arduino based pcb with the purpose of using a ds3231 temperature compensated RTC to wake up and put to sleep an atmega328p-au which will then control a MOSFET which connect to the ground side of a micro servo to turn it on/off. It's my first design so before I make a prototype I would like to take your opinion about it (attached an online gerber viewer for you guys to take a look Here ).

Board size: 45mm*16mm

So I've drawn an arduino based pcb with the purpose of using a ds3231 temperature compensated RTC to wake up and put to sleep an atmega328p-au which will then control a MOSFET which connect to the ground side of a micro servo to turn it on/off. It's my first design so before I make a prototype I would like to take your opinion about it (attached an online gerber viewer for you guys to take a look Here ).

Board size: 45mm*16mm

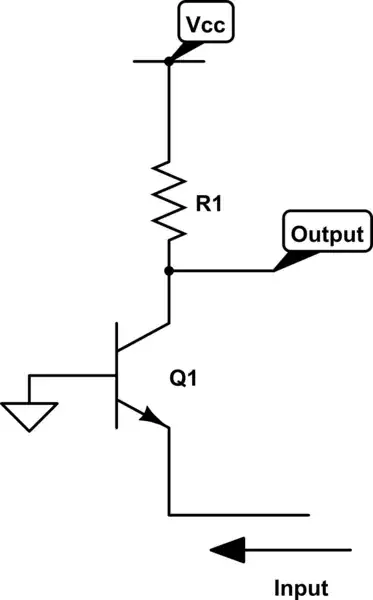

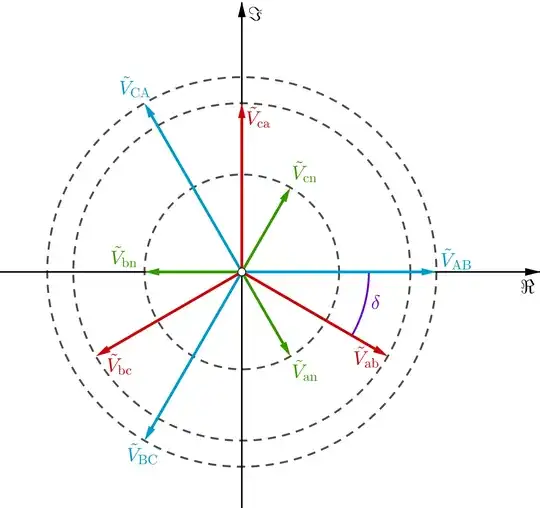

so the rtc send signals from its digital and analog pins to the arduino, which use that to drive on/Off the MOSFET gate. apart from the motor who have a peak of 1A @5V, everything else is relatively low powered (with a maximum of 40-50mA) . What I'm worried about is interference which might trigger or prevent the trigger of the ds3231 to the MCU. here are more pictures if you don't want to check the gerber:

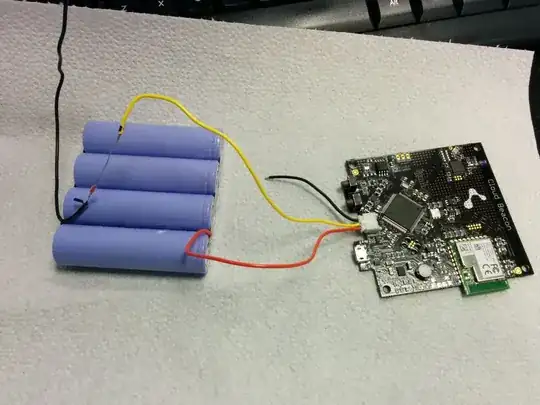

Sorry for my poor formatting: it's my first time over here. Thank you for your help! The servo (mg90s microservo) is going to be off for like 59min each hour and when it turns on it only do so for a few minutes. I started from the pro mini official drawings and went from there. I used the breadboard prototype I did as a reference for connections. I understand I got a lot to learn. The shipset is in sleep mode almost all the time.

I'm afraid of unwanted noise on the digital pins or A4 A5 which might cause unwanted behaviour(early wake ups).It's powered by batteries. do I risk a lot of noise over the long D2 line Due to the ground plane under the IC1? do A4/A5 have a risk of being affected by noise ? how can I fix that in that case?