I wanted to operate remotely a motor which is controlled by a manual key switch (still in place in case the automated way fails - which happened).

I though by replacing it by basics relay commanded by wifi would have suit the need. I used sonoff 4ch pro r2 board with the following relays:

Even if the rating is different I thought I would give it a try - at worst the relay die and I change it to suits the same rating as the initial key switch.

However the replacement did not failed where I expected it initially.

Again, the idea was to mimic the work of the manual key switch.

The motor board has (4 inputs: +24VDC, GND, CMD CW clockwise, CMD CCW counterclockwise) CMD CW and CMD CCW are set to +24VDC to instruct the motor. The relays (RLY1 & RLY2) of the sonoff card is sending the +24VDC to the right CMD. Hardware exclusion makes it impossible to have CMD CW and CMD CCW up at the same time:

I powered the board with the same line as the motor. I knew it was risky because the voltage on this line has a motor on it. But still, it worked quite well for a long time.

I was just finishing to pair the sonoff with a rf433 when I started to test the motor and the C23 starting to fumes.

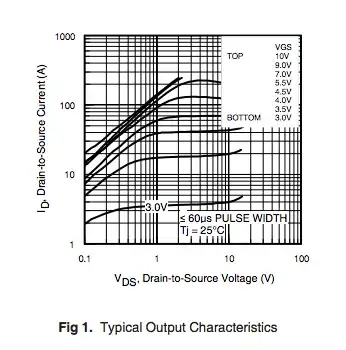

From my basic understanding: C23 (45uF 35V) is there to absorb small voltage fluctuation. It burned A: because the voltage was too high or B: voltage was negative.

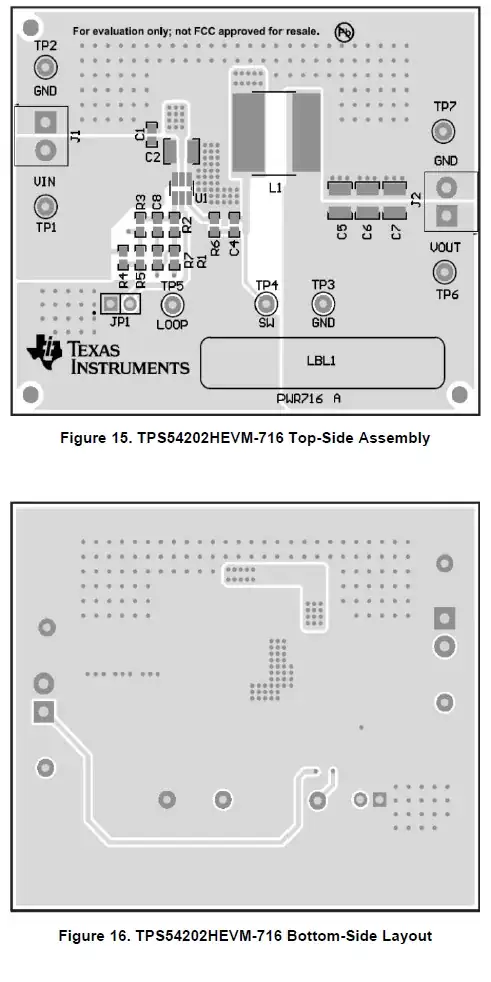

Q1: Is there a chance that only the C23 is to replace ? Or should I start to think to change voltage regulator MP2307DN too ? This is SOC so I think it will be quite difficult for my level of soldering.

Q2: Should I think to change the capacitor and the regulator by something different to ensure protection or how can I protect the circuit from surges and ensure this will never happen again ?