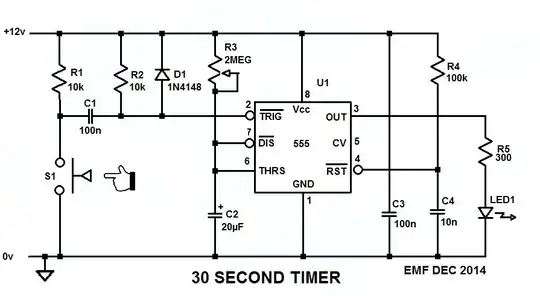

I made the following circuit. STM32's are STM32F103C8T6 (Blue Pills). I left out the obvious wires:

- All four components grounded together

- Supplied 5V to RX TJA 1050 from RX STM32

- Supplied 5V to TX TJA 1050 from TX STM32

simulate this circuit – Schematic created using CircuitLab

The TJA's are these ones:

Most important software running on TX STM32:

/* CAN init function */

static void MX_CAN_Init(void)

{

static CanRxMsgTypeDef CanRX;

static CanTxMsgTypeDef CanTX;

CAN_FilterConfTypeDef sFilterConfig;

hcan.Instance = CAN1;

hcan.pRxMsg = &CanRX;

hcan.pTxMsg = &CanTX;

hcan.Init.Prescaler = 8;

hcan.Init.Mode = CAN_MODE_NORMAL;

hcan.Init.SJW = CAN_SJW_1TQ;

hcan.Init.BS1 = CAN_BS1_12TQ;

hcan.Init.BS2 = CAN_BS2_5TQ;

hcan.Init.TTCM = DISABLE;

hcan.Init.ABOM = DISABLE;

hcan.Init.AWUM = DISABLE;

hcan.Init.NART = DISABLE;

hcan.Init.RFLM = DISABLE;

hcan.Init.TXFP = DISABLE;

if (HAL_CAN_Init(&hcan) != HAL_OK)

{

_Error_Handler(__FILE__, __LINE__);

}

sFilterConfig.FilterNumber = 0;

sFilterConfig.FilterMode = CAN_FILTERMODE_IDMASK;

sFilterConfig.FilterScale = CAN_FILTERSCALE_32BIT;

sFilterConfig.FilterIdHigh = 0x07ff;

sFilterConfig.FilterIdLow = 0x0000;

sFilterConfig.FilterMaskIdHigh = 0x07ff;

sFilterConfig.FilterMaskIdLow = 0x0000;

sFilterConfig.FilterFIFOAssignment = CAN_FILTER_FIFO0;

sFilterConfig.FilterActivation = ENABLE;

sFilterConfig.BankNumber = 14;

if (HAL_CAN_ConfigFilter(&hcan, &sFilterConfig) != HAL_OK)

{

Error_Handler();

}

}

In main:

..

hcan.pTxMsg->StdId = 0x100;

hcan.pTxMsg->ExtId = 0x01;

hcan.pTxMsg->IDE = CAN_RTR_DATA;

hcan.pTxMsg->IDE = CAN_ID_STD;

hcan.pTxMsg->DLC = 2;

while (1)

{

hcan.pTxMsg->Data[0] = 0x10;

hcan.pTxMsg->Data[1] = 0x1;

HAL_CAN_Transmit(&hcan, 10)

HAL_Delay(1000);

}

And on TX STM32 the same code for initializing the CAN, and following code in main:

if (HAL_CAN_Receive_IT(&hcan, CAN_FIFO0) != HAL_OK)

{

Error_Handler();

}

void HAL_CAN_RxCpltCallback(CAN_HandleTypeDef* CanHandle)

{

if ((CanHandle->pRxMsg->StdId == 0x100) &&

(CanHandle->pRxMsg->IDE == CAN_ID_STD) &&

(CanHandle->pRxMsg->DLC == 2))

{

printf("1");

}

However, the callback is never called.

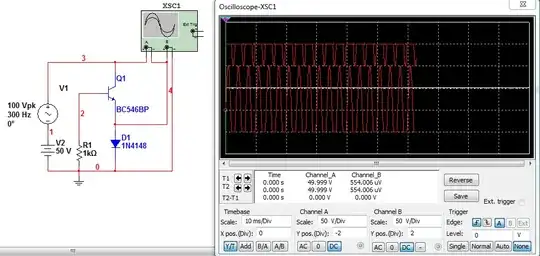

What I see with a logic analyzer:

- CANH (Channel 2) and CANL (Channel 0) receive info

- Channel 4 is connected to RX STM32, CAN RX and does not receive anything

I see X's in the screenshot below, not sure if this is a problem.

What I did

- Replaced TJA's, no difference

- Put breakpoints on various places, everything seems ok, except the callback

Question:

- What should I change to be able to receive info at RX STM32, CAN RX?

Update

I found out there is some transmission problem:

within

HAL_StatusTypeDef HAL_CAN_Transmit(CAN_HandleTypeDef* hcan, uint32_t Timeout)

there occurs a timeout (last line):

while(!(__HAL_CAN_TRANSMIT_STATUS(hcan, transmitmailbox)))

{

/* Check for the Timeout */

if(Timeout != HAL_MAX_DELAY)

{

if((Timeout == 0U) || ((HAL_GetTick()-tickstart) > Timeout))

{

hcan->State = HAL_CAN_STATE_TIMEOUT;

/* Cancel transmission */

__HAL_CAN_CANCEL_TRANSMIT(hcan, transmitmailbox);

/* Process unlocked */

__HAL_UNLOCK(hcan);

return HAL_TIMEOUT;

}

}

}

I have not found out where this error comes from.

Also because of the error, nothing is send afterwards.

No more time now, I will check more tomorrow or Tuesday evening.

Other checks:

- Oscilloscope: not checked yet

- Resistance between CANL and CANH: 61.4 ohm (while not transmitting), when transmitting slightly less.

- Voltage while not sending between CANL and CANH is 0 V

- Adding a 120 R resistor between CANL and CANH does not make any difference (still a HAL_TIMEOUT).

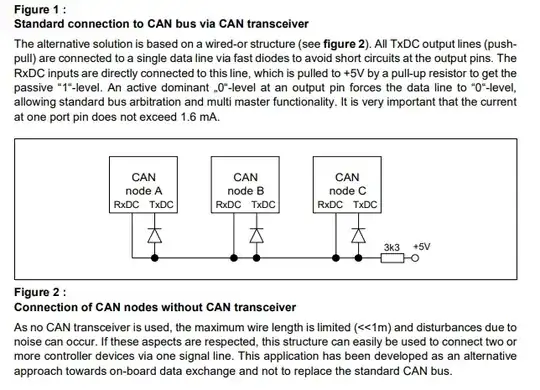

Update

Still limited time, but I did a test without using transceivers, but directly with a simple circuit as described in this document (thanks to Maple). Relevant part:

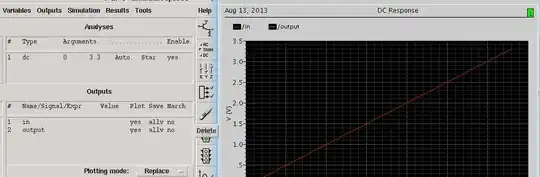

However the result is still not working. The receiver sides are ALMOST equal, but the transmitter transmits barely nothing

- Channel 1: Transmitter TX

- Channel 2: Transmitter RX

- Channel 3: Receiver TX

- Channel 4: Receiver RX

On the detail (below), in the selected ramp there can be seen a slight difference (there are more of those). Since they are connected together, I would not expect these though, but maybe my cheap logic analyzer (5$) might cause these.