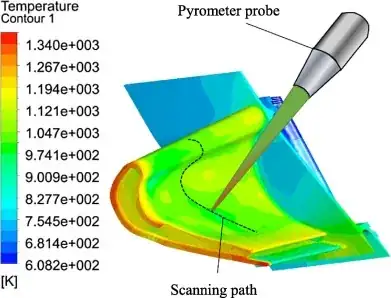

I already have pyrometer in place, but I want to know the temperature distribution inside the mold (I have cooling and heating sections).

[from O.P.'s comment under an earlier answer]

and

I'm looking for a wireless, relatively small (think a quarter dollar size) temperature sensor capable of withstanding and measuring temperatures up to 600 °C (1100 °F).

Let's separate the two problems: measuring high temperature, and electronics working at high temperature.

Thermocouples themselves can survive at 600 °C and make measurements. Thermocouples can be made quite small.

You would need to choose between grounded or floating thermocouples (see also discussion here). Grounded thermocouples have a faster response time. Floating thermocouples can work with simpler signal conditioning circuitry.

You would need to insulate the thermocouple wires from each-other and from the metal mold. So, you will need electrical isolating material which can survive 600 °C. Ceramics and glass can do that.

Thermocouples need signal conditioning circuitry to make measurements. Silicon semiconductors will not survive at 600 °C, as it was already mentioned in a previous answer. You will either need to insulate your electronics, or keep the electronics in a cool place and connect it through long thermocouple wires.

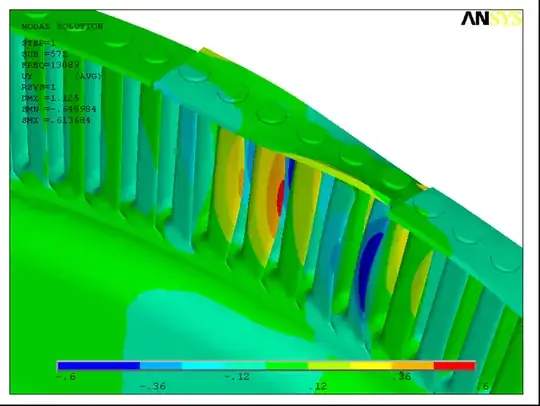

A lot of the arrangement would be defined by the mechanics of your casting process. Is the mold spinning? Is it running through a conveyor? And such questions.

The mold is mounted on a rotating machine, and the temperature outside the mold is higher (it is heated by several burners).

[from O.P.'s comment under the question]

Perhaps you might build a thermally insulated path for the thermocouple wires along the axis of rotation of the machine. (If you post more about your mold and the rotating machinery, we might be able to say something more concrete. Pictures usually help.)