I'll use current as an analogy for heat flow. From Wikipedia:

The heat flow can be modeled by analogy to an electrical circuit where heat flow is represented by current, temperatures are represented by voltages, heat sources are represented by constant current sources, absolute thermal resistances are represented by resistors and thermal capacitances by capacitors.

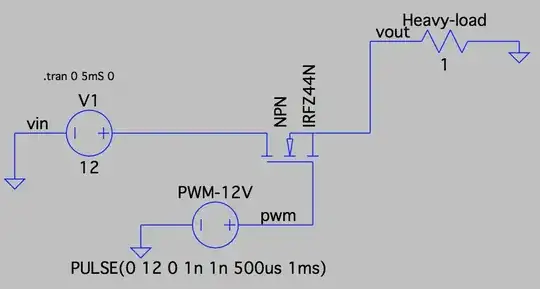

All the following circuits are simulatable, you can run the DC solver and it will give you temperatures in "Volts". :D

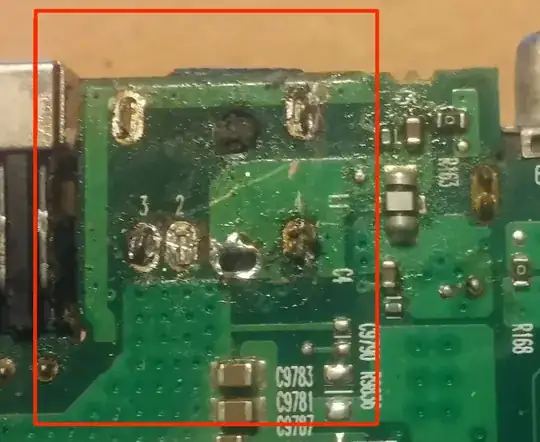

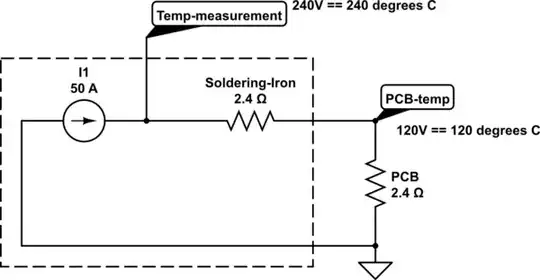

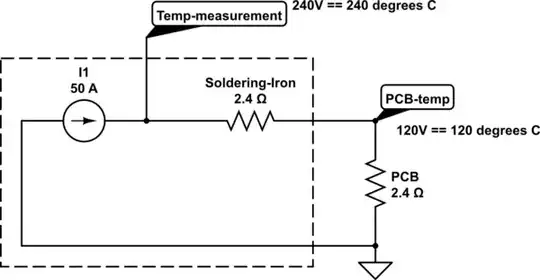

A VERY rough model of your current setup

Lets assume 50W == 50A. I Guessed a total thermal resistance so that the reading on your soldering stating would give 480ºC. (unit for thermalr sistance would be K/W, I'm ignoring ambient temp and a lot of things, but anyhow).

Your soldering tip has a high thermal resistance and the board has a low thermal resistance, so even though the iron is measuring 480ºC in its tip, the PCB is at a much lower temp.

simulate this circuit – Schematic created using CircuitLab

How to transfer more heat to the board?

Lower the thermal resistance of your tip! That's how tinning your tip to get more surface, fatter tips, etc help. Let's say 2.4K/W is the absolute best tip you can get. Still, 50W is not enough to reach a solderable temperature. (But see that the proportion of temperature got better, you are at 50% of the tips temperature now instead of 25%).

simulate this circuit

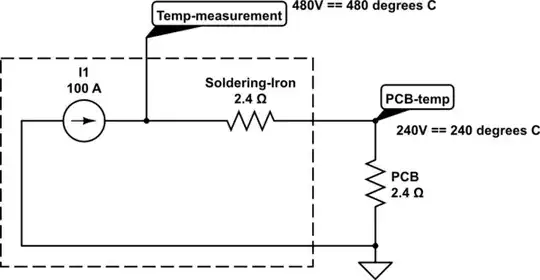

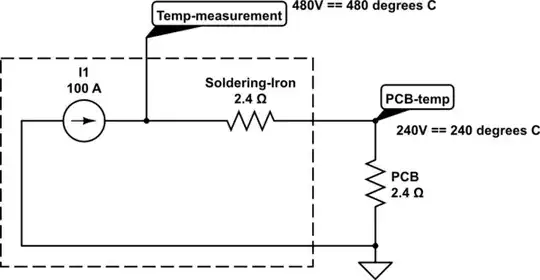

What would more Watts give you?

Since 50W is not enough to heat very low thermal resistance objects (big planes of copper). You add more power until you can reach 480ºC at the reading point. Note that if the object had higher resistance you would need less power.

simulate this circuit

Preheating the board

I think this would a very rough model for a pre-heated board:

simulate this circuit

Note how you need less power than the previous example AND that the temperature "proportion" is better.

So in essence, when dealing with heavy temperature sinks:

- More power is good if you can deliver it without losses.

- To lower the losses: a fatter tip, better contact, no wind.

- Higher target temperature: preheat!

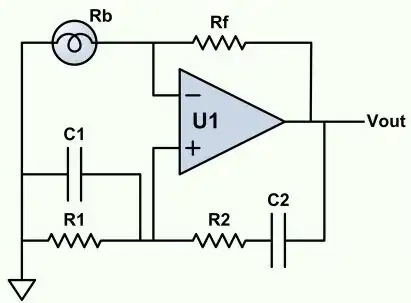

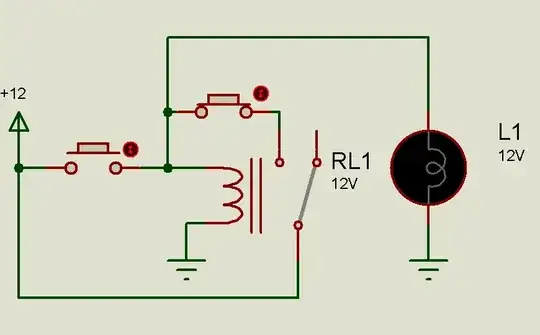

Some stations (I use an ERSA i-con) have internal presets for different tips, because they have profiles of temperature loss and transfer and try to compensate for that.

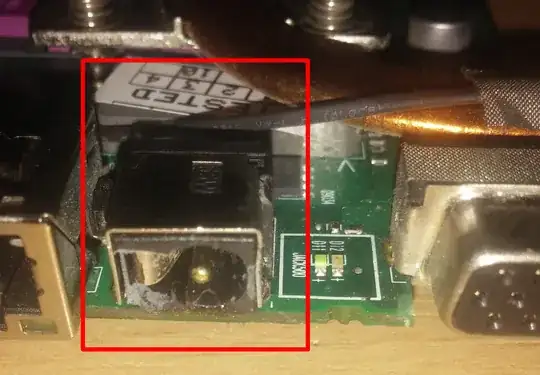

See that it has 2 numbers:

Both read 350ºC, but one is the sensed temperature, the other is the set temperature. So, in case that the power is not enough (As in the example that only reached 240ºC), you could read it out. IRC, those chinese soldering stations blink between sensed and set temperature, but I'm not sure.