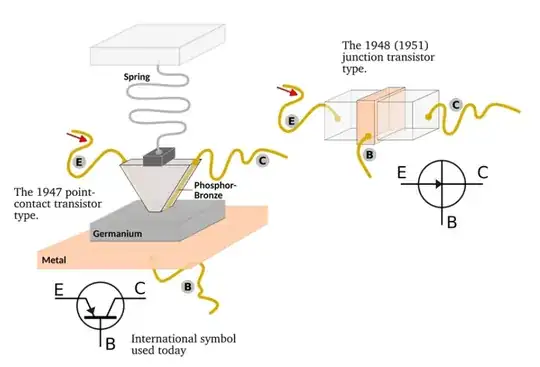

Below on the left side of the illustration there is a point-contact transistor which is the first transistor invented in 1947:

It seems the symbol of BJT actually comes from this point-contact transistor even though they operate very different way.

But what is the purpose of using a "spring" for establishing contacts?

In this source it is written:

The whole triangle was then held over a crystal of germanium on a spring, so that the contacts lightly touched the surface.

Is that the reason for using the spring? To ensure a weak touch to the germanium surface? But if so, why is a weak/lightly touch is needed?

Edit:

Another source from page 201 of the book called "Conquering the Electron":