Using electric motor to adjust blinds

The blinds I'm working with don't require much strength to pull down, but a fair bit to pull them up (using the little string/cord), So I'll need something fairly powerful, but slow.

Cord pull in kg ~= (Torque in N.cm)/10 on a 1 cm RADIUS = 0.8" dia drum

Cord pull in pounds = kg x 2.2

Bigger drum = smaller pull. Smaller drum =- bigger pull.

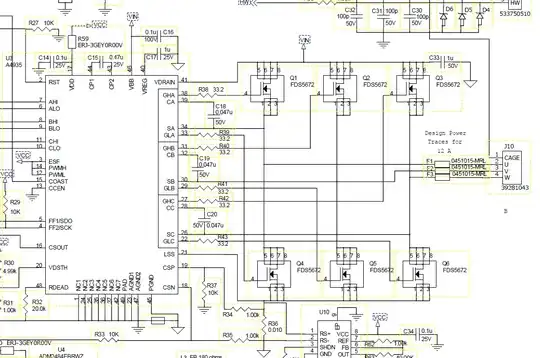

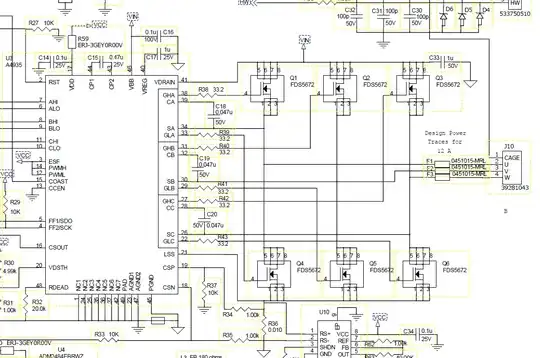

Torque on your chart is given in N.cm (chart image at end)

kg.cm ~ N.cm/10

1cm radius = 2cm diameter ~= 0.8 inch.

So, if you have a 0.8 inch diameter or 2 cm diameter drum for the cord then the cord pull in kg = N.cm/10.

So a 20 N.cm motor will provide 2 kg cord pull.

Pounds force ~= kgf x 2.2

Kg to Pounds: Double pounds, THEN add 10%.

eg 2 kgf -> 2 x2 = 4, +10% = 4.4 lbf

5 kgf = 11 lbf etc.

Looking at their 1st line of motors you have torques including

25, 50, 100, 300, 900 N.cm

= 2.5, 5, 10, 30, 90 kg.cm

= same cord pull on a 1cm radius = 2cm dia = 0.8 inch dia drum.

= 5.5, 11, 22, 66, 198 lbf cord pull.

Use a fishing scale (as DeanB suggests) or tie on bottles of water or exercise weights or ... to get some idea of needed oull.

I'd expect 2.5 kg to be low, 10 kg to be getting OK, 90 kg to be tearing the cord off. YMMV.

Double drum dia = half cord pull.

Halve drum dia = double cord pull.

DIY

You can make your own rotary to linear gearboxes using threaded rod.

Rotate a captive nut on a rod and rod moves.

Rotate a captive rod in a nut and the nut moves.

Simple pulley speed reductions from motor to rod increase overall effective reduction.