I'm working on a setup, where we need communication between a master device and several slave microcontrollers distributed out in different boxes connected by "long" cat5e cables (3-10 meters) The microcontroller boxes (MC-boxes) should be hot-pluggable, such that the master device can communicate with whatever is connected at any time. The MC-boxes need not to communicate with each other.

We have achieved this in the comfortable and controllable surroundings of our office in an I2C-based setup, utilizing the TI's P82B715 I2C extenders. However, we've observed that this solution is not reliable in noisy environments where the I2C-bus locks up within hours or days requiring a hard reset.

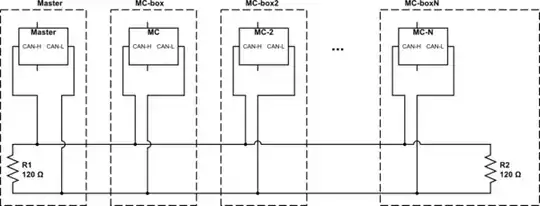

Thus, I have started looking into differential signaling protocols due to their inherent noise resilience. CAN-bus seems especially interesting due to it's error handling capabilities. And, as far as I have read, it should be possible to make devices on a CAN-bus hot-pluggable (several comments in this post also states so). However, in our application, the bus cannot be laid out beforehand, but should be extended as MC-boxes are dynamically added. The CAN spec states that the bus should be terminated by two 120Ω resistors, which makes the dynamic expansion troublesome. So, how can I achieve something like that, I have tried to depict below?

simulate this circuit – Schematic created using CircuitLab (PS: The boxes don't have to be daisy-chained like shown above)

Thus, my questions are:

- How can I achieve an extendable CAN-bus, that retains the constant impedance on the signal lines as required by the spec, when new 'boxes' are added or removed?

- Can I achieve the above with a completely different protocol?

I hope you are able to help!

Edit - Clarifications: - The master unit will be connected to the internet, so I have some security concerns with using IP-based protocols such as TCP and UDP. - The boxes should be water-proof, so all electronics must be kept inside the boxes.