TL;DR Use BJTs for linear operation, not FETs

Most FETs are not rated for safe operating area (SOA) at DC. Bipolar junction transistors (BJT) are.

If you examine the SOA graph for any FET, you'll find a set of curves for pulses of duration 1 µs, 10 µs, 1 ms, etc., but rarely any curve for DC. You can try to extrapolate to 'near DC' if you like, at your own risk. It means the manufacturer is not willing to put a figure on how much dissipation is allowed in DC operation.

It's often said that FETs parallel nicely, because of their positive resistance temperature coefficient. As they get hot, their resistance increases, so the current will decrease in the hot one, and the situation is stable. FETs are made of multiple paralleled cells internally, so they share OK as well, right? Wrong!

It is only for the temperature coefficient of resistance. FETs also have another temperature coefficient, which is the temperature coefficient of the threshold voltage, and that's negative. As the FET heats up, at constant gate voltage, it draws more current. When the gate voltage is very high, saturating a switched FET, the effect is minimal, but when the voltage is down around the threshold, it is very strong. As one cell heats up, its current increases, so it heats up some more and has the potential for thermal runaway, where one cell tries to hog the entire current through the device.

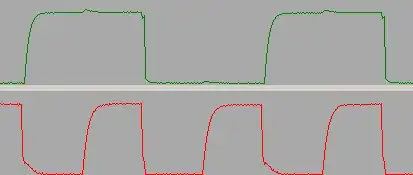

This effect is limited by two things. One is that the die tends to start at the same temperature all over if it hasn't been subject to uneven heating. So it takes time for the instability to grow. This is why short pulses can use more power than long pulses. The second is the thermal conductivity across the die, which tends to even out the temperature across it. This means that a certain threshold power level is needed for the instability to grow.

BJT manufacturers tend to put a figure on this power level, but FET manufacturers don't. Perhaps it's because that the DC SOA level is a much smaller fraction of its 'headline' power dissipation in FETs that it would be embarrassing to spell it out. Perhaps it's because in linear operation, so many advantages of a FET fall away that it's only worth using BJTs for any specific power level that there's no commercial incentive for them to qualify FETs for DC use.

Part of the reason that BJTs can have a large area stable junction and FETs don't is down to the way they work. The 'threshold' for BJTs, the 0.7 V Vbe, is a function of the material, and it is very consistent across the large die. The threshold for FETs depends on the the thickness of the thin gate layer, which is a manufactured dimension, poorly defined (you know how wide the specification for FET Vgsth is in a data sheet!) by being the small difference between two large diffusion steps.

That said, there are some FETs that are characterised for DC use. They are few and far between, and they are very expensive, compared to their switching-optimised brothers. They will have had more testing and qualification, and use a different process that sacrifices low on resistance and some other beneficial FET traits.

Use a Darlington transistor if you want low base drive current. The extra 0.7 V min Vce is largely irrelevant given that you're going to be operating it linearly.

If you still want to use a switching FET for DC operation, then stick to 5% to 10% of the headline dissipation. You may well get away with it.

Janka asked an interesting question in comments, 'what about an IGBT?'. According to this app note, No detailed characterization of IGBTs as linear amplifiers has been carried out by IR, given the limited use of IGBTs in this type of application.

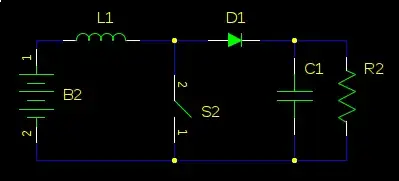

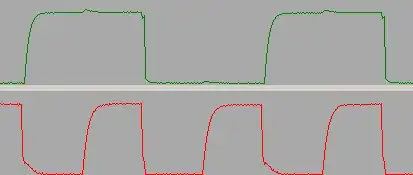

The VI graph from this data sheet for the NGTG50N60FW-D

shows the typical inflection at 9.5v \$V_{GE}\$ that characterises thermal instability, at 8v an increase in temperature from 25C to 150C results in a tripling of collector current, which sounds fairly unstable.

However, the SOA graph

does have a DC line, and that line is at just over 200Watts, the headline power of the device. Have they characterised it properly?

An IGBT requires no current to drive it, but does need more gate volts than a Darlington needs base volts, so may or may not be easier to drive. At the moment, I've not found any definitive information on IGBTs in this mode of operation.