I have 8 thermistors and I must make sure that each of them is inside a temperature window. They all have the same window and I don't care which or how many are inside the valid range, I just need to know if all of them are inside the (same) window or not. This is to be a hardware-only solution, so software-sequencing of ADC reads is out of the question.

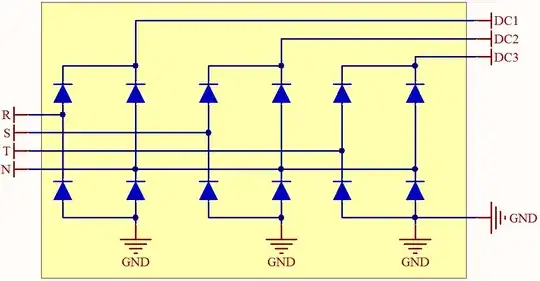

My best solution currently is to use a bunch of comparator ICs and implement a separate window-comparator for each thermistor. To optimize the solution, I can use a number of quad comparators, each with an open-drain output so that I can connect them all up. Still, in essence it is the same circuit. The reference/trigger voltages I can make once, buffer, then supply to all comparators.

I do feel stupid for just simply throwing a bunch of comparators at the problem. I am not sure if there isn't any better way, I'm mostly trying to optimize board space. Is there some creative way you know? For example, select min/max voltages of all thermistors and use a single window comparator (EDIT: two comparators ofc), which IMHO would lead to a larger solution and is thus not a good answer, I'm just mentioning this for inspiration.

EDIT: I know that a software-based solution would be the best. That is why I mentioned it right in the beginning and upfront to prevent everybody suggesting it. The reason the problem is defined this way is because this is a safety circuit, and specifications require me to implement a hardware-only solution in addition to a software-monitor. So the software-based solution is already there, I "just" need to find the best way to implement the hardware-based one.