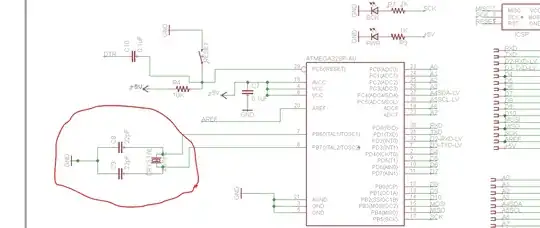

One thing I might change (others may have different advice) would be to rotate the capacitors both 180 degrees, so that their ground pads are close together. This would require you to move the crystal and caps a bit farther away from your IC to be able to route, but give them the same ground reference to each other. I would also place a ground via near the two pads.

EDIT

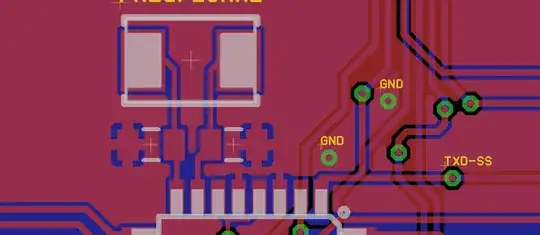

Based on your second photo, I notice that your ground stitching is minimal. Think about how traces slice up your ground plane, and how you can use vias and the plane on the opposing side of the board to "stitch" these slices back together. A few example stitching vias are added in light blue in the image below:

Take the area just below your logo; there are many traces running horizontally on the top side of your board, with red plane split above and below. Placing two vias on either side of the traces uses the bottom ground plane to attach the red pieces back together.

I would recommend not following my example exactly, but instead use it to think about how you can connect your two ground planes together as well as possible, ideally everywhere. This involves finding a balance between maximum number of vias (don't turn your board into swiss-cheese), and best possible stitching.