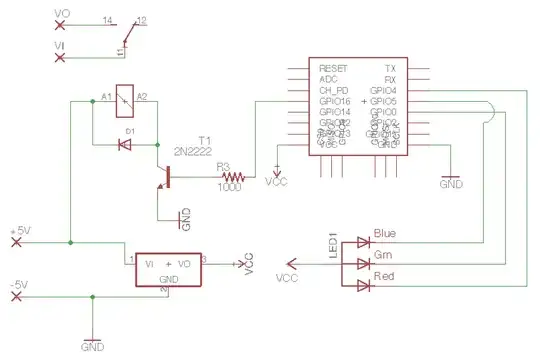

You ask about the circuit, but your schematic is too much of a mess to get into that.

Engineering requires attention to detail. For good results, this must be carried out thru the whole design process. A messy schematic is either the product of messy thought, or a Eh, it doesn't matter attitude. Either results in a bad design.

Problems with the schematic include:

- No component designators on some parts. This looks like it was done in Eagle. Eagle makes it very easy to show component designators per part. There is no excuse for this.

- The labels for the pins sticking out the bottom of the large block collide with the labels of the pins sticking out the side. Surely you could see this for yourself.

- The GND symbol below T1 is sideways. You clearly had room to make it right side up. In fact, that would have been simpler. This makes it more effort to look at your schematic, and is just rude.

- The flow around T1 is right to left, although it's not a feedback path. It is nice to keep logical flow left to right when possible, and it certainly could have been here with a little re-arranging of parts.

There are some glaring problems with the circuit too, but once you take some care with the schematic, you may find them yourself.