I would like to measure and log the ignition advance timing angle of a vintage (70s) car. That is, mechanical distributor points (Kettering system), no electronic ignition, no RPM sensor.

For this, amongst other things, I need to monitor the signal that is sent from the ignition coil via the distributor points to spark plug #1, which determines the start of the ignition event for my purposes.

This signal is coming from the secondary side of the coil, and it's a periodic pulse signal in the order of kV. A single period looks like this:

Essentially, I want to convert the burn line region on the picture to a square signal of TTL level, which I can then read with a microcontroller.

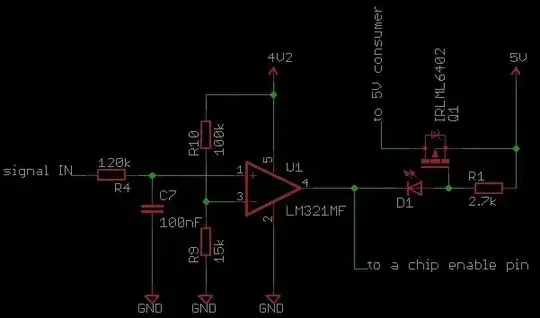

This question and its answer explain a way how to do that for the primary side of the coil. As the secondary side mirrors the primary side, the concept of how to condition the input signal is the same: add low pass filtering, clamp the maximum and minimum voltage with diodes, buffer and convert to square wave with a Schmitt trigger.

However, the main difference here is that while the primary magnitudes are in the order of tenths of volts, the secondary ones are in the order of kilo Volts.

This brings a whole new set of considerations: obviously if not managed safely, it can pose a risk to the signal conditioning electronics, or more importantly, to the person handling them.

My experience is with lower voltage signals, and I'm assuming that there has to be more thought put into it than simply adding more attenuation (or optoisolation) to the signal going into the microcontroller.

This "Testing your ignition with an oscilloscope" document (coincidentally, the same vintage as the car) describes part of what I'm trying to do. On page 5, section Connecting the scope, a homemade pick up capacitor is coupled to the ignition wire. I'd like to think technology has advanced since the 70s and there is a more refined way of doing it. Furthermore, I do not often drive with tin foil wrapped around engine wires :)

How would I best go about:

- Measuring the signal with a scope for testing/prototyping? Using a capacitive or inductive probe with built-in attenuation?

- Permanently connecting, i.e. interfacing the signal to a microcontroller for monitoring purposes? I'm not asking for an actual circuit (*), rather a recommendation on the best way to physically connect the signal from the ignition cable to the stage that would condition it before going into the microcontroller, which would sit in a box in the engine compartment. Would that be the same answer as the oscilloscope question? I. e. capacitive/inductive probe? Or a regular resistive attenuator?

Thanks.

(*) although suggestions are welcome.