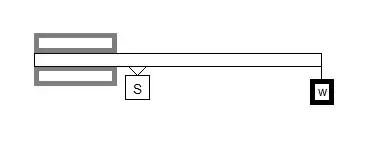

I have a setup where I need to measure the weight at the end of an arm.

The arm is clamped between two pieces of aluminum at one end. The Sensor S is mounted a short distance (5cm?) from the aluminum base. The distance from the sensor to the end of the arm is 25cm.

The weight at the end of the arm ranges from 1kg to 100 kg. I'd like to measure it with an accuracy of 0.1kg.

How do I calculate what kind of range my sensor should have?

How do I select the best sensor for this application?