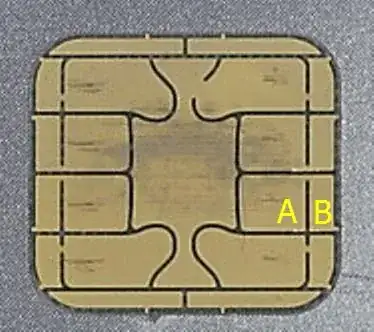

Here's a scan of a "chip-and-pin" Visa Electron contact pad

It looks like a metal plate divided into regions by narrow cuts. Look for example at regions marked A and B - there's a cut between them but it only separates them partially and there's a narrow metal bridge left on the top of the cut.

That looks strange. If the regions have to be connected why not just omit the cut entirely and have one single region?

Maybe it's for cleaning contacts of the reader - as they pass over the cuts the dirt if any gets scrapped of them, but I'm not sure.

What's the reason for this design? Why are the regions partially separated by a cut yet there's a conductive bridge left between them?