I am having difficulty measuring current into an IoT device that I am making. I need to be able to gather data about power consumption over time, and about the sleep mode current. I was trying to use a shunt resistor to gather the current data, but I am running head first into a problem with Georg Ohm, and all of his laws.

In sleep mode, my device should use about 800 µA of current, my not so accurate PSU is saying that it is outputting about 2 mA, so maybe I have a bit more coding to do. However during sleep mode, at seemingly random intervals the modem will turn back on for a brief moment and transmit, (standard deep sleep modem behavior). This transmit burst can be up to about 1.5 A.

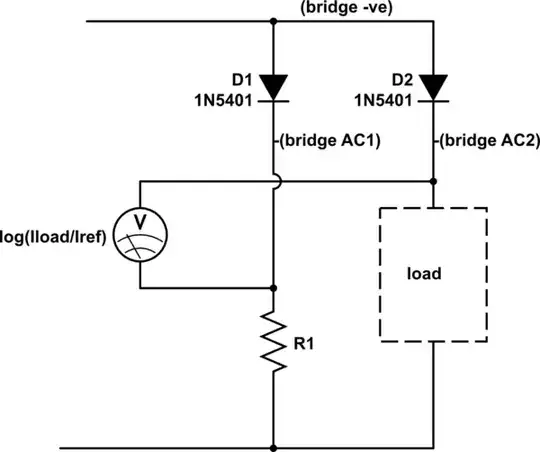

Anyway, I am having a problem using a shunt resistor because a voltage drop that allows me to see any meaningful data on sleep current, drops so much voltage during a transmit burst that my device restarts.

Could anyone recommend a way to measure current such a large current range?

Device specifications:

- Sleep mode current: 600 µA - 3 mA

- On current: 27-80 mA

- Transmit burst: up to 1.5 A

- Voltage: 2.6 V - 4.2 V

- Charge current: 400 mA