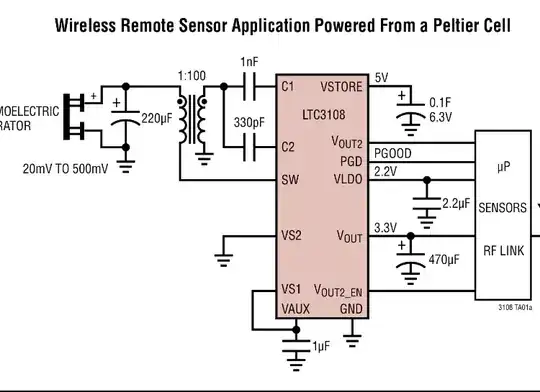

First off, Würth's datasheet is fine and perfectly complete. It doesn't list primary and secondary windings because those are totally arbitrary. You happen to be using the low inductance winding as primary, but someone else might want to use the high inductance winding as primary. They expect you to know which winding you want to use for what purpose.

The windings are clearly labeled as 1 and 2, and the information for each of these is listed in the table. Winding 1 is the low inductance winding, so pins 1 and 2 connect to your 22mV energy source. Winding 2 is the high inductance winding, so pins 3 and 4 connect to the LTC3108.

If you're getting 10mV out, then that means the LTC3108 isn't getting enough voltage to bootstrap itself. I have used the LTC3108 personally, and its a very nice part and works very well - as long as you prototype with it correctly.

You cannot build switching DC/DC circuits on breadboards. Even if they work, which is rare, it will be so far from how it would behave as a real, well-routed circuit board as to not really even be useful for prototyping. And what you've built will, unfortunately, simply not work. Switching circuits demand critical paths be short as possible, and I mean you want to make them on the order of a few millimeters. All the jumper wires I see in that photo are over an order of magnitude longer than the longest path length I would ever expect to work. They add too much parasitic inductance.

But, you especially cannot build a circuit involving the LTC3108 (or energy harvesting in general) on a breadboard. At 22mV, you have 2mV of room. Assuming you have clean wires, clean breadboard contacts (which is almost never the case - plus parts that were on cut tape will still have adhesive on their leads which will get stuck in the holes of a breadboard when you insert them), and a very good connection, the spring contacts of a breadboard are still going to be, at best, 50mΩ connections. That's per contact. So you're looking at 100mΩ just to connect two things together. And I know those jumper wires, I have a bunch myself, and they're just straight up terrible. Very thin gauge. Thin pins on the end that are tinned and don't have any better surface contact plating.

All that adds up to enough resistance to consume your 2mV headroom from as little as milliamps of current flowing. And, indeed, the output voltage will be roughly the input voltage when the LTC3108 can't startup, so it would look like closer to 10mV is being wasted - and with minimal current flowing.

But, as I said, even if you get the resistances much much lower (you must solder these connections, spring contact connections are just not going to cut it), you will need to do this dead-bug style where you can solder stuff directly to other things without using jumpers and keep the path lengths much shorter.