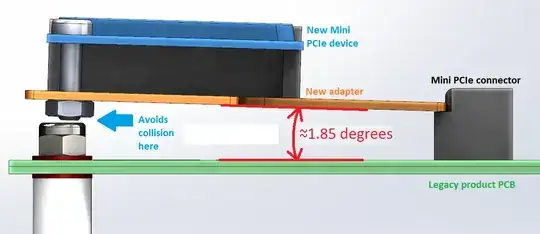

I have a mechanical problem with securing a Mini PCIe card into an adapter which then goes into a legacy product's connector.

Look carefully at the orange PCB in the picture below and you'll notice that the screw passes through a cranked out "wing" that sticks out of the side of the adapter and fouls the pillar in the legacy product...

If I tilt the adaptor by 1.85 degrees or so then I can clear the pillar but I'd rather have the Mini PCIe laying parallel to the carrier board if possible.

Our normal method is to use M2.5 machine screws, nuts and washers, but in this situation an existing M3 pillar is colliding with the new M2.5 screw, so I need an alternative.

Is there a fastener type that can fit a pair of concentric M2.5 mounting holes but leave minimal material sticking out of the holes?

Notes:

There is almost no wiggle-room to move things around, the legacy device was never anticipated to have to support this new device and so I'm basically painted into a corner. I have no more than 0.5mm freedom in any axis on any feature!

Doing it this way means I don't have to take the legacy device's threaded pillar out. Removing that pillar would be a major hassle during the upgrade of hundreds of units. With this hack I can reduce a 15 minute installation to less than 3 minutes! But it is still a hack and that's nagging away at me.

Edit: @Transistor's suggestion looks like it'll do the job...

Might put a dab of silastic in the gap to stop it rattling :)