I made a controller for 12V DC fan. It is basically a buck DC-DC converter controlled by voltage. It regulates voltage for fan from 3V (lowest speed, fan draws 60mA @ 3V) to 12V (full speed, fan draws 240mA @ 12V). This controller works well, it controls fan speed as expected. I tried to make some filtering but there is still some significant noise polluting my 12V rail. How to minimize it?

SW_SIGNAL is just a PWM signal, where duty cycle is set by other circuit.

Problem is at point A. Inductor L1 is meant to filter that noise, it works but not so good as I expected:

So the noise is lowered from 6V p-p down to 0.6V p-p. But 0.6V is huge noise.

It is related to the operation of buck converter, not the fan itself. I tried to put a 47Ω 17W resistor instead of the fan and the noise is still there. I was using scope probes with the smallest spring contact to minimize the loop.

The noise goes away only in case there is 100% PWM duty cycle, what is obvious, because 100% PWM stops switching.

UPDATE:

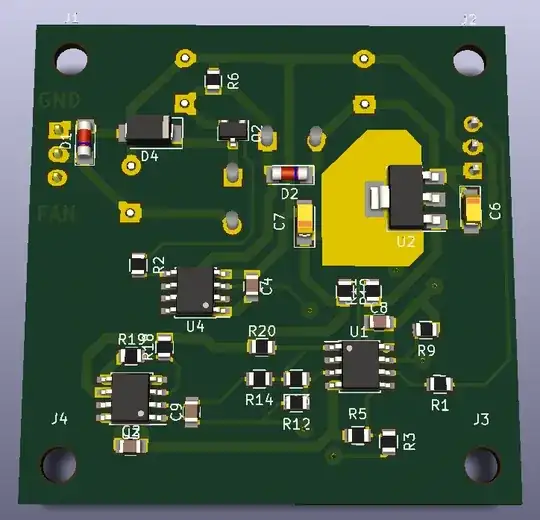

This is the layout (upper part is the buck convertor, fan connector at the left side, 12V power input at the right side):

I used generic electrolytic capacitors. I have no datasheet for them.

I used generic electrolytic capacitors. I have no datasheet for them.

I have added 10uF ceramic capacitors to C1 and C3.

I have increased value of R2 from 0Ω to 220Ω.

Changed D4 from US1G to SS12. My mistake, I used US1G originally.

And the noise went under 10mV (resistor was used instead of fan).

After I plugged fan instead of power-resistor:

UPDATE2:

I was using 130kHz switching frequency in my circuit. And rise/fall times were 10ns.

Yellow trace = gate of switching transistor Q2.

Blue trace = drain of Q2 (10ns rise time).

I changed frequency to 28kHz (I will need to use bigger inductor because of this change), and increased rise/fall times to 100ns (I achieved it by increasing value of resistor R2 to 1kΩ).

The noise decreased down to 2mV p-p.