In my previous question I focused on lead-based solder alloys (see Best solder wire - Sn63Pb37 vs Sn60Pb40 vs ...?).

Some of you brought new exciting solder alloys to my attention. The two most promising types contain either Bismuth or Indium.

Some questions:

How do they compare to each other on properties like:

- wetting of pads and pins

- interaction with fluxes

- joint strength - brittleness (is this directly related to the "tensile strength (PSI)" column in the table below? Please enlighten me.)

- price

- ...

How do they compare to standard solder alloys, like Sn60Pb40?

Any drawbacks?

Most of them are sold without flux core. Wouldn't that make the solder process very difficult?

What kind of flux should one use with Bismuth and/or Indium based solders?

Note:

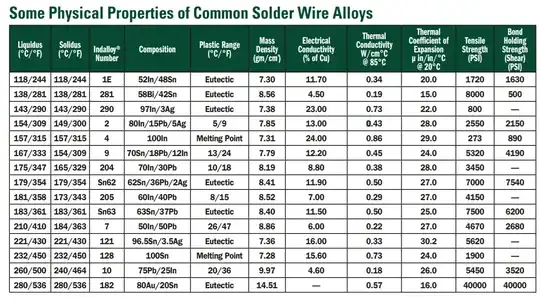

Perhaps the following table might be of help:

This table comes from "Indium Corporation".