Boost circuits definitely do stress the components a lot. It's a fact of life. That form omits some important parameters such as average current and inductor ripple. Average current creates heat and this is separate from max current capability.

Do note that the output diode is the hottest component of a boost converter. Also the diode specs need to be considered carefully. 5A diode will usually NOT survive 5A current as it will overheat and die. On that kind of current you need to start paying attention to heat dissipation solutions, using PCB surface copper is a popular solution as it requires no extra hardware. For high power loads it may not be sufficient.

You may want to try texas webench which will give you thorough analysis of the circuit you need.

When the boost circuit component stresses get out of control, it would be time to start considering a flyback which will do the voltage stepping "for free". It's a more complex beast of course with that coupled inductor and all.

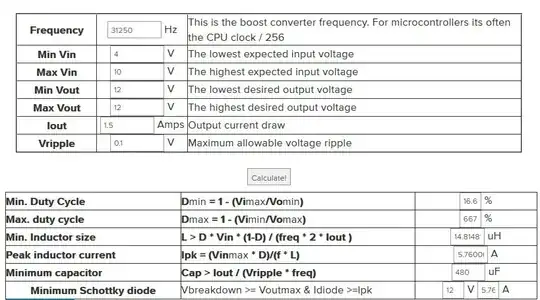

Texas SLVA372C gives you basic equations for determining boost converter values.

http://www.ti.com/lit/an/slva372c/slva372c.pdf

Diode current rating equaling the output max current is indeed sufficient in theory but in reality will overhead without a cooling solution. Check datasheet for thermal parameters, they usually give you temperature rise values for "minimum" PCB footprint and with a blob of surface copper to dissipate the heat.