I have been having problems with 2N7000 mosfets that perform perfectly on the breadboard, but when moved to a perfboard start failing. I'm on my third iteration now, replacing all mosfets, between iterations having eliminated possible other sources for failure. On my third attempt I've been probing each separate mosfet for shorts and testing them with the uC between soldering the next. After soldering the third of eight in total, all three suddenly failed. This time they failed having not a shorted gate-drain, as before, but turning the gate ON/OFF has no effect, current now always flows from Drain to Source. I'm quite desperate at this point. :(

- I've always been very careful with ESD, always handling the mosfet by the plastic, not the pins. Last run I moved my soldering iron to a grounded socket.

- Before starting handeling components and soldering, I always ground myself by touching the ground prong on the wall socket.

- I've reduced soldering temperature to 250 C.

- For testing purposes I'm switching an 1mA LED, at 24V (I verified the current).

My setup is as follows: A microcontroller* provides 0/5 volt to the gate of the mosfet (100ohm resistor on that). On the Drain, there's the LED with a current limiting resistor. Source is connected to ground. Basically there are no other components.

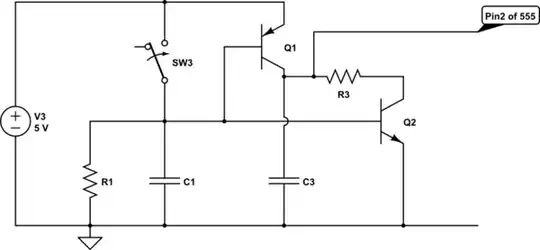

simulate this circuit – Schematic created using CircuitLab

Since everything is OK on the breadboard, and things start failing after soldering, but never after the first mosfet. I'm fairly confident that something goes wrong during soldering. What could I possibly do wrong here?

*) To be precise, an PCF8547 connected over i2c to an 5V Arduino.

EDIT: I verified that the wall socket is actually grounded.

UPDATE: I decreased temperature to 250C, no luck. I'm fairly sure that I'm not a source of ESD as I'm grounding myself throughout the soldering process, before and after. My suspicion is now on the cheap (but grounded) soldering iron. I'm going to replace it with a soldering station soon, hope that helps. Any additional insights/tips are welcome, I'll keep monitoring this topic and post new findings when the soldering station is in. I may also get some ESD workplace stuff like a strap, I have still to check what's available in this department.

EDIT & UPDATE: Decreased temperature further down to 250C. Now waiting for delivery of two new soldering irons.