I'm measuring a thermocouple which connected series with a heating element. Heater is driven with PWM and when PWM is off-duty, a measurement is taken through output A0 using an ADC.

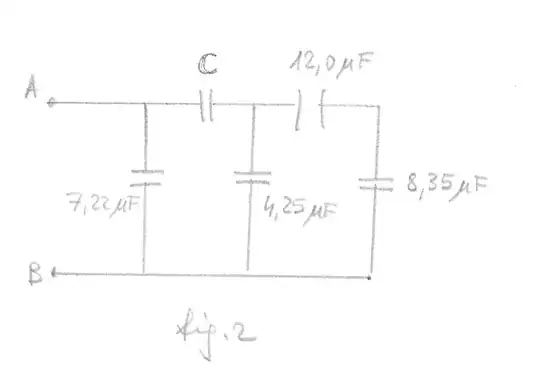

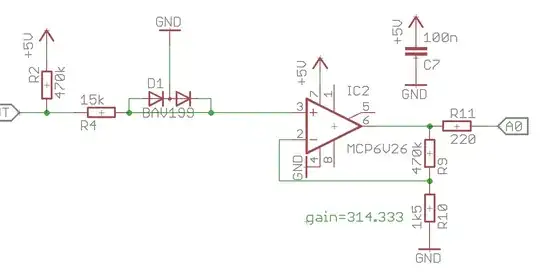

Relevant parts of the circuit can be seen below.

I think it is a fairly standard op-amp application. The BAV199 double diode is clamping the input to a safe level (~900mV) for the opamp input (because heater is driven with higher voltage than opamp's supply).

Since this non-inverting setup requires relatively high gain to measure small thermocouple signal, output is easily saturates when heater is powered on.

The problem is, when heater is powered; op-amp "see" this clamped ~900mV at input, because ~300 gain it overloads and it is taking a long time to recover.

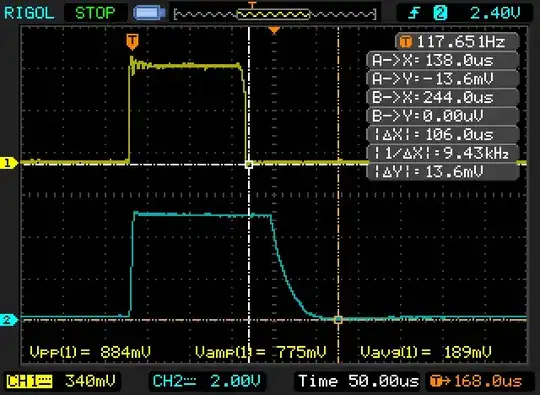

The yellow trace is op-amp input, blue is output. Total settling time is around 100uS, which is ruining my PWM strategy at high duty cycles. Also, when (I think) op-amp recovers from overdrive, it also takes a long time to reach correct values (I mean the curve, which is starting from trigger point to second cursor and takes 50uS).

I can't explain these results, probably because I'm not experienced in analog domain. (software guy here)

I'm using MCP6V26, according the datasheet "Output Overdrive Recovery Time" is 45uS typ. and "Slew Rate" is 1V/uS. Especially the slew rate, which I'm associating with the "decaying" signal at the end of blue trace; does not match up the datasheet values.

It also has 2MHz bandwidth and I'm only using ~100Hz PWM frequency; so it shouldn't be a problem there.

Given this input and output requirements;

- Am I doing something horribly wrong,

- If not, can I get faster output response from this setup

- Is there a more appropriate approach to doing this (in hardware perspective)

Thanks.