Note that this is a theoretical question - there is no schematic I can show. I will show some schematic, but it will be a very simplified version of an actual circuit, only for illustration purposes.

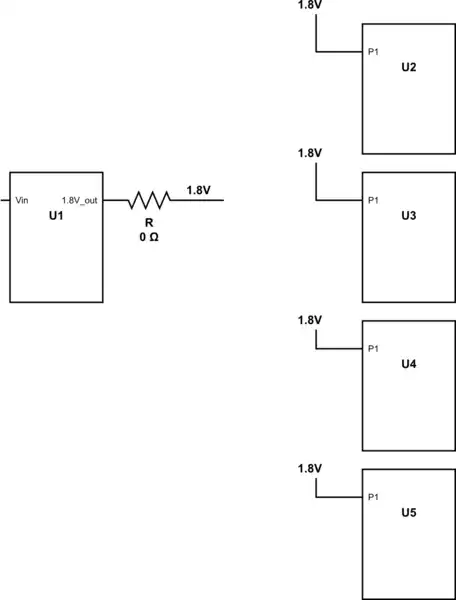

Assume I have a voltage converter that takes as an input my main voltage (from a power supply) and outputs a certain voltage, for example 1.8V. It would look something like this:

simulate this circuit – Schematic created using CircuitLab

When connecting my circuit to the P.S, I notice it draws too much current (the P.S shows that).

Since I have multiple voltage converters in my circuit (not shown here), I check resistance between each output of each converter to ground. I see that the resistance between 1.8V to ground is almost 0 Ohms. Now I know the fault is either in the voltage converter or one (or more) of the other components drawing power from that 1.8V.

I desolder the resistor shown in the image to disconnect the converter from the other components and see that the converter is fine, but checking resistance from the point connected to all those components still shows 0 Ohms.

My question is - how would you check which component is the faulty one, without desoldering each suspicious component? As you can see in the image, the 1.8V supply is connected directly to the components, without a resistor/bead.

For the sake of this question, assume I have access to whatever equipment needed (no matter how pricey). I wouldn't want solutions to be limited due to availability of equipment.

Thank you!