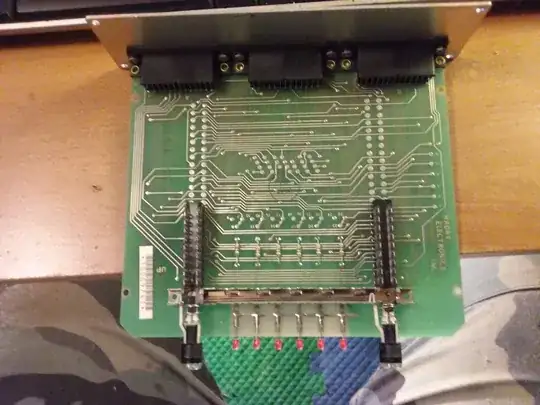

I am planning to use this spring terminal block:

Voltage and current requirements: 220 VAC 5 amps max

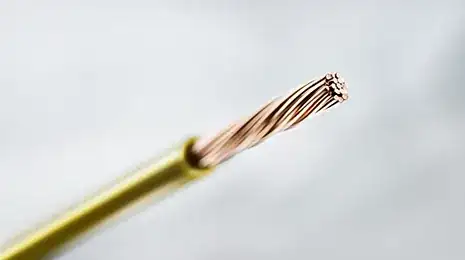

Wire type : Multi strand wire - 1 sq mm to 1.5 sq mm like this:

Datasheet says that I can use 0.2 sq mm to 2.5 sq mm:

I have never earlier used spring terminal blocks. Online reading suggested use of ferrules for multi strand wires in some articles but other articles and youtube videos were fine with directly stripping and inserting the stranded wires.

What is the preferred way to use such connectors with multi strand wires?